The Deflection Temperature Under Load (DTUL) test is one of the methods used to measure the heat resistance of plastics. In this test, a specified flexural stress is applied to the sample in a three-point bending setup, and the temperature is gradually increased. The temperature at which the deflection under load exceeds a certain value is measured. This test is used to evaluate the heat resistance of plastic products, such as microwave-safe plastic dishes, commonly found in daily life.

In addition to the DTUL test, other methods for measuring the heat resistance of plastics include the Vicat Softening Temperature (VST) test and the Ball Pressure (BP) test. This page provides a detailed explanation of each testing method.

Table of Contents

Overview and Principle of Testing

DTUL – Deflection Temperature Under Load Test

(Reference Standards: JIS K 7191-1,2,3 / ISO 75-1,2,3 / ASTM D648)

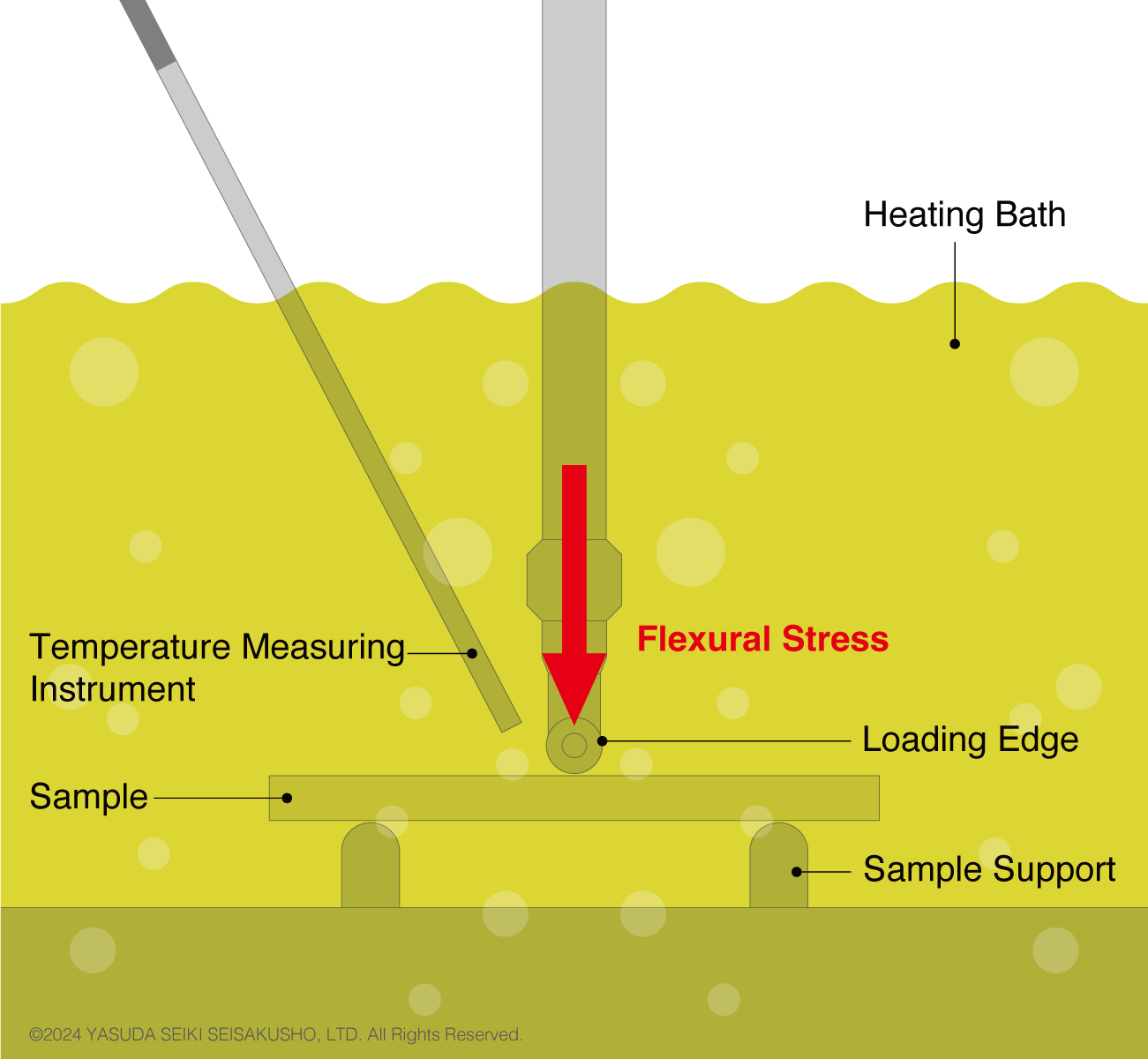

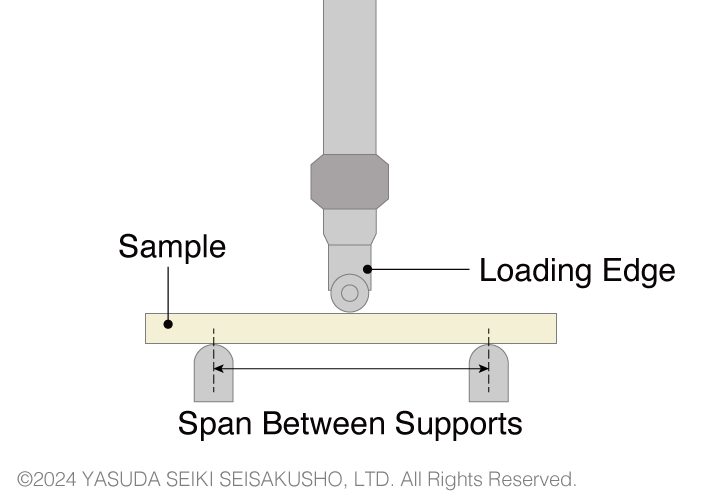

The Deflection Temperature Under Load is measured by applying a specified flexural stress in a three-point bending setup and gradually increasing the temperature. The test measures the temperature at which the sample reaches a specified deflection amount, known as the Deflection Temperature Under Load.

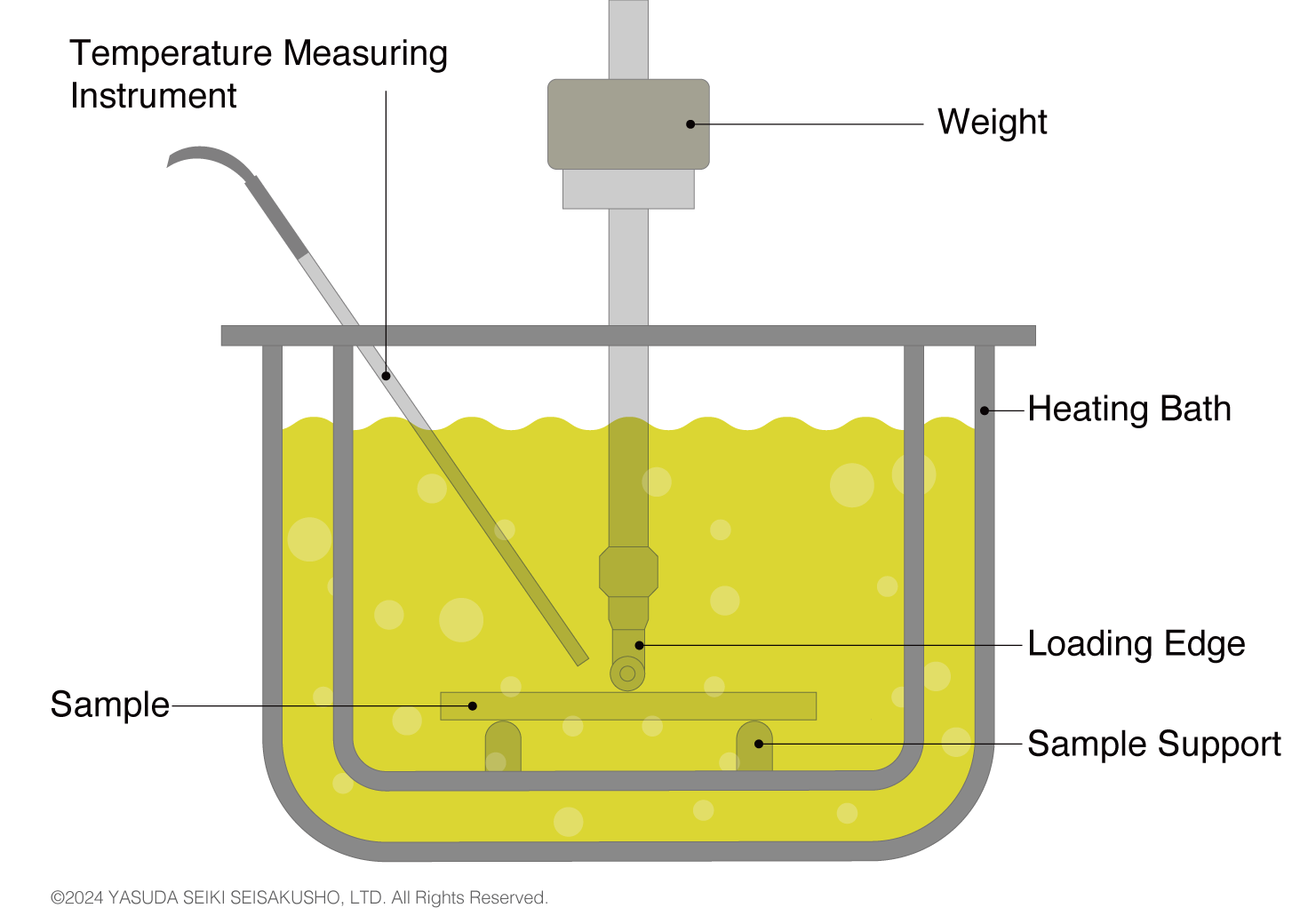

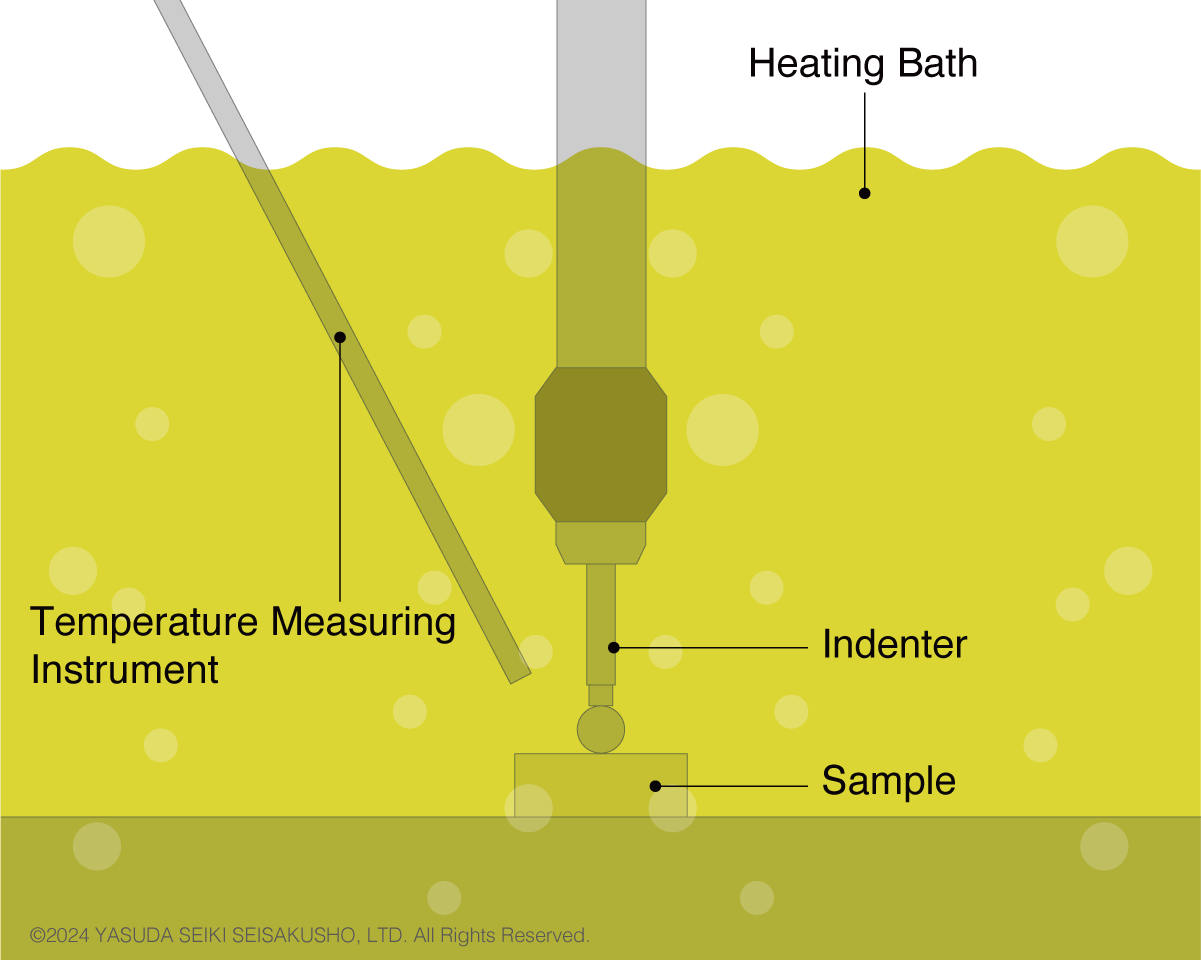

Structure of the Testing Machine

Example of a Deflection Temperature Under Load Testing Machine

Example of a Deflection Temperature Under Load Testing Machine

The basic structure of the testing machine is shown in the diagram above.

The load application system consists of a flexural stress load frame, thermometer, load shaft, weights, loading edge, and sample supports. The weights are placed on top of the load shaft, and a loading edge is attached to its tip. The sample supports are fixed to the bottom of the frame. Additionally, the heating bath is equipped with a control system that allows the temperature to increase at a constant rate of 120±10°C/h.

Test Method

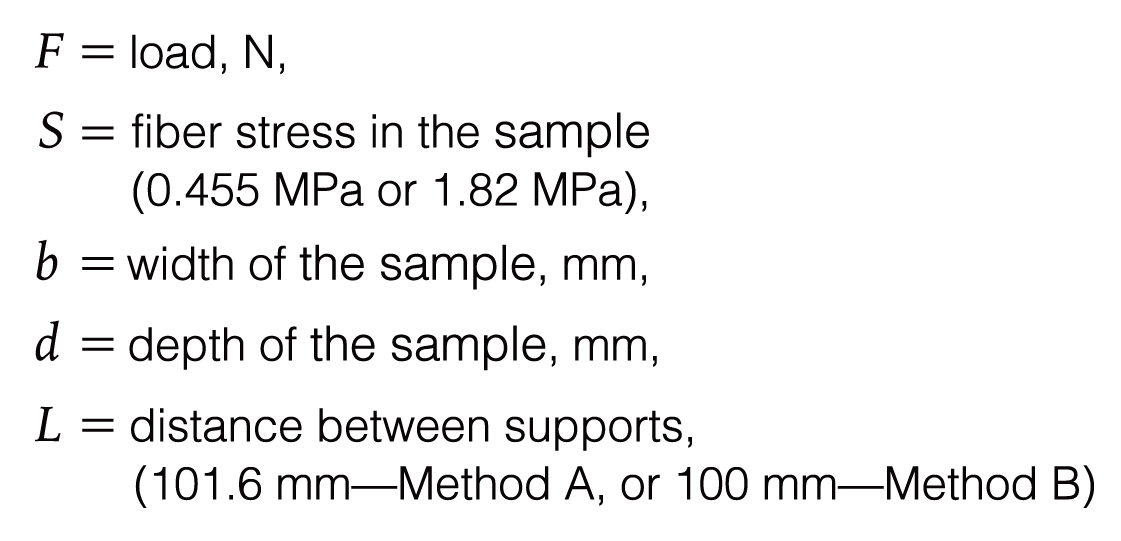

The load is applied to the sample so that the specified flexural stress is generated in a three-point bending setup. The stress applied to the sample should meet one of the following conditions:

-

JIS/ISO Standard

- Method A: 1.80 MPa (recommended value)

- Method B: 0.45 MPa

- Method C: 8.00 MPa

-

ASTM Standard

- 0.455 MPa

- 1.82 MPa

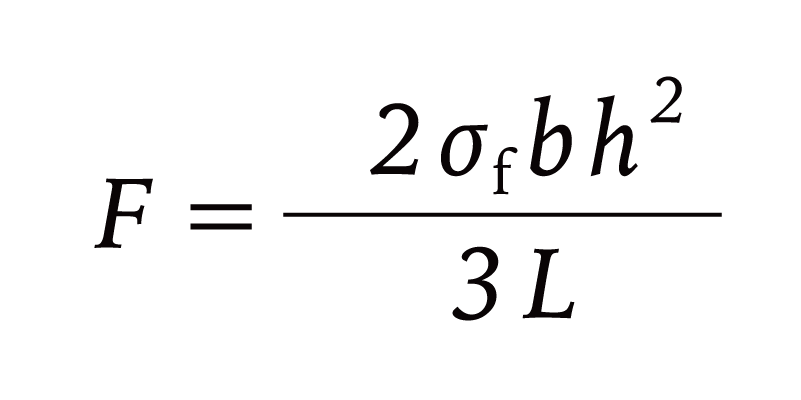

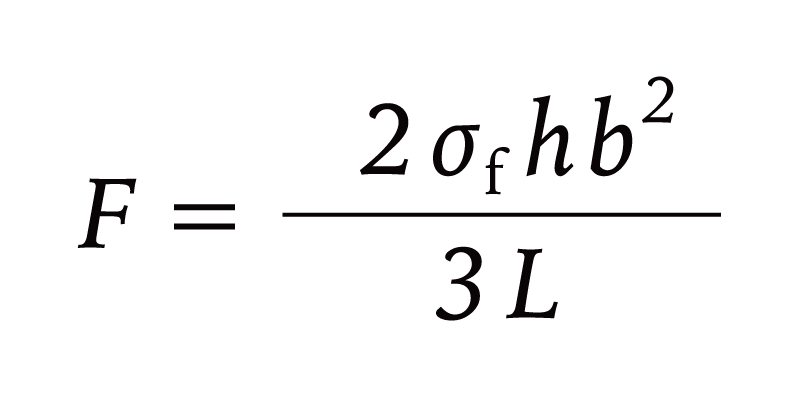

The load is calculated using the following formula:

【JIS/ISO Standard】

【ASTM Standard】

Measurement Method

Place the sample on the sample supports. The sample is loaded with weights and inserted into the heating bath. The temperature is increased at a constant rate of 120±10°C/h. The temperature at which the sample deflection reaches the specified value (Deflection Temperature Under Load) is measured.

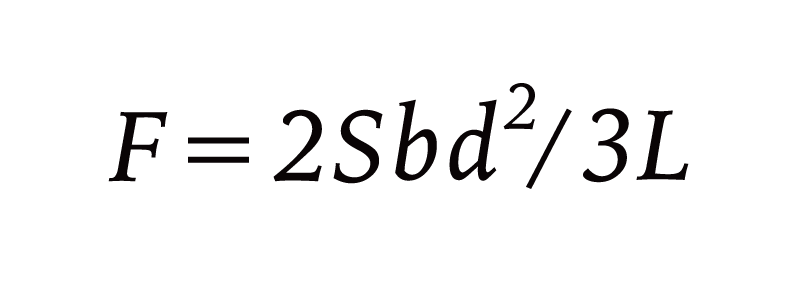

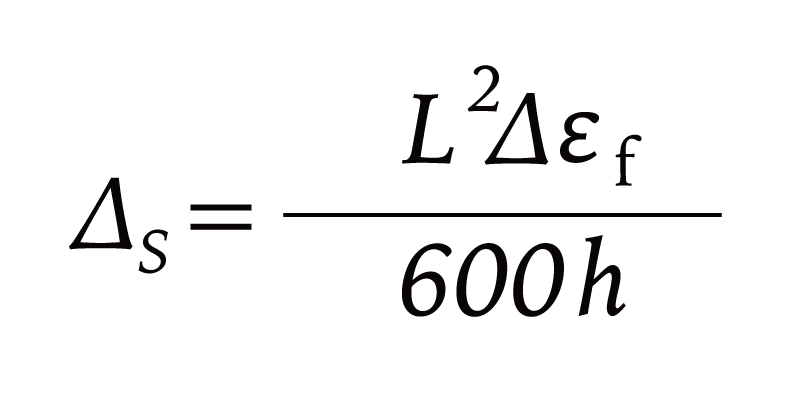

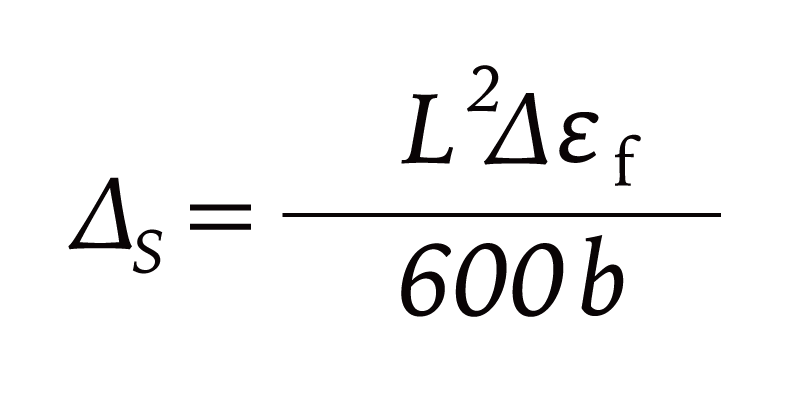

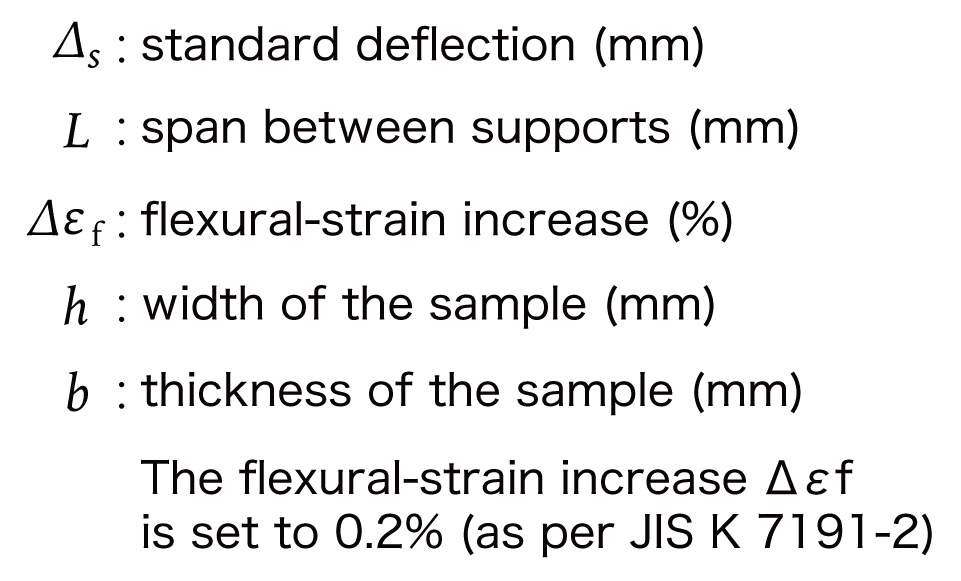

The standard deflection is calculated using the following formula:

【JIS/ISO Standard】

※For ASTM, the standard deflection is 0.25 mm.

VST – Vicat Softening Temperature Test

(Reference Standards: JIS K 7206 / JIS K 6742 / JIS K 6816 / ISO 306 / ISO 1452-1,2 / ISO 2507-1 / ASTM D1525)

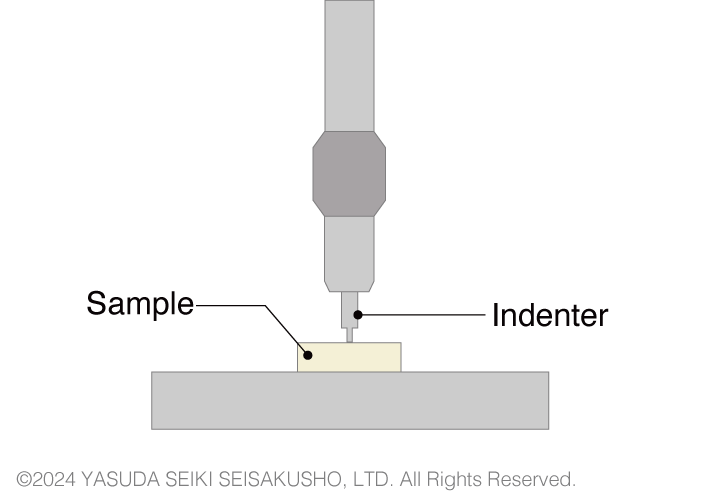

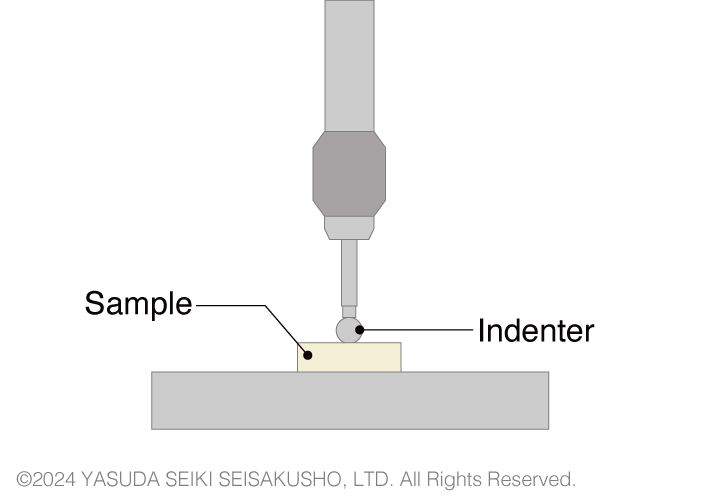

The Vicat Softening Temperature (VST) is the temperature at which a 1.0 mm penetration is achieved by the indenter into the surface of the sample under gradually increased temperature while a load is applied. The VST test evaluates the temperature at which thermoplastic materials begin to soften rapidly.

The test methods are classified into four types: A-50, A-120, B-50, and B-120, each with specified loads and heating rates (JIS/ISO).

Note: ASTM does not classify test methods like JIS/ISO, but specifies the same loads and heating rates.

| JIS K7206 /ISO 306 / ASTM D1525 | ||

|---|---|---|

| Test Methods (JIS/ISO Only) | Load | Heating Rate |

| Method A50 | 10±0.2N | 50℃/h |

| Method A120 | 10±0.2N | 120℃/h |

| Method B50 | 50±1N | 50℃/h |

| Method B120 | 50±1N | 120℃/h |

BP – Ball Pressure Test

(Reference Standard: Electrical Appliances and Materials Safety Act (2014) Appendix Table 3 Method B in the report on “The registration system for ball pressure temperature of thermoplastics used in electrical appliances and material.”)

In this test, a steel ball indenter with a 5 mm diameter is used. A load of 20+0/-0.4N is applied to the heated sample for one hour, and the temperature at which the indent diameter on the sample surface reaches 2 mm is measured.

Note: IEC 60335-1 and Electrical Appliances and Materials Safety Act (2014) Appendix Table 3 Method A uses a different procedure with a system of weights designed to apply a downward force while placed in an oven, differing from the above test content.

List of Standards

Standards for measuring the heat resistance of plastics exist in both JIS (ISO) and ASTM. Both standards include test methods for DTUL and VST. The Ball Pressure Test is specified in the Electrical Appliances and Materials Safety Act.

| Standard | Year | Test Method | Standard Name | |

|---|---|---|---|---|

| JIS | K7191-1 | 2015 | DTUL | Plastics-Determination of temperature of deflection under load- Part 1: General test method |

| K7191-2 | 2015 | DTUL | Plastics-Determination of temperature of deflection under load- Part 2: Plastics and ebonite | |

| K7191-2 | 2007 | DTUL(EW) | Plastics-Determination of temperature of deflection under load- Part 2: Plastics and ebonite AppendixA | |

| K7191-3 | 2007 | DTUL | Plastics-Determination of temperature of deflection under load-Part 3: High-strength thermosetting laminates and long-fibre-reinforced plastics | |

| K7206 | 2016 | VST | Plastics-Thermoplastic materials- Determination of Vicat softening temperature (VST) | |

| ISO | ISO75-1 | 2020 | DTUL | Plastics — Determination of temperature of deflection under loadーPart 1: General test method |

| ISO75-2 | 2013 | DTUL | Plastics — Determination of temperature of deflection under load — Part 2: Plastics and ebonite | |

| ISO75-3 | 2004 | DTUL | Plastics — Determination of temperature of deflection under load — Part 3: High-strength thermosetting laminates and long-fibre-reinforced plastics | |

| 306 | 2022 | VST | Plastics — Thermoplastic materials— Determination of Vicat softening temperature (VST) | |

PVC Pipe and Plastic Pipe Related Standards

| Standard | Year | Test Method | Standard Name | |

|---|---|---|---|---|

| JIS | K6742 | 2016 | VST | Unplasticized poly(vinyl chloride) (PVC-U) pipes for water supply |

| K6816 | 2008 | VST | Thermoplastics pipes and fittings- Test method for Vicat softening temperature | |

| ISO | 1452-1 | 2009 | VST | Plastics piping systems for water supply and for buried and above-ground drainage and sewerage under pressure — Unplasticized poly(vinyl chloride) (PVC-U) — Part 1: General |

| 1452-2 | 2009 | VST | Plastics piping systems for water supply and for buried and above-ground drainage and sewerage under pressure — Unplasticized poly(vinyl chloride) (PVC-U) — Part 2: Pipes | |

| 2507-1 | 1955 | VST | Thermoplastics pipes and fittings — Vicat softening temperature — Part 1: General test method | |

Test Conditions

DTUL – Deflection Temperature Under Load Test

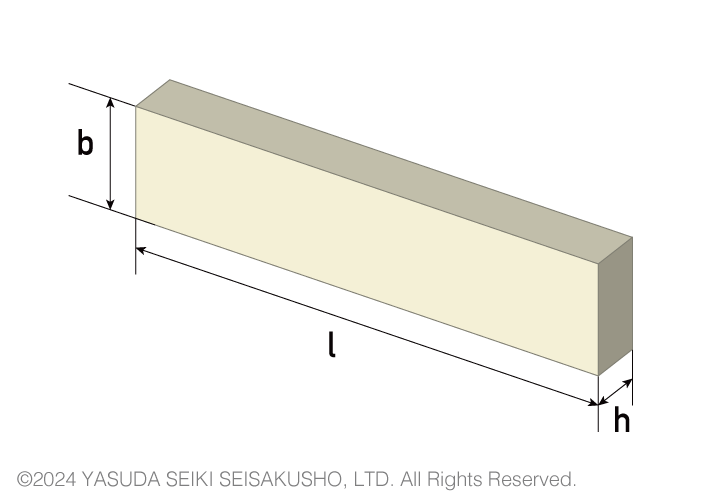

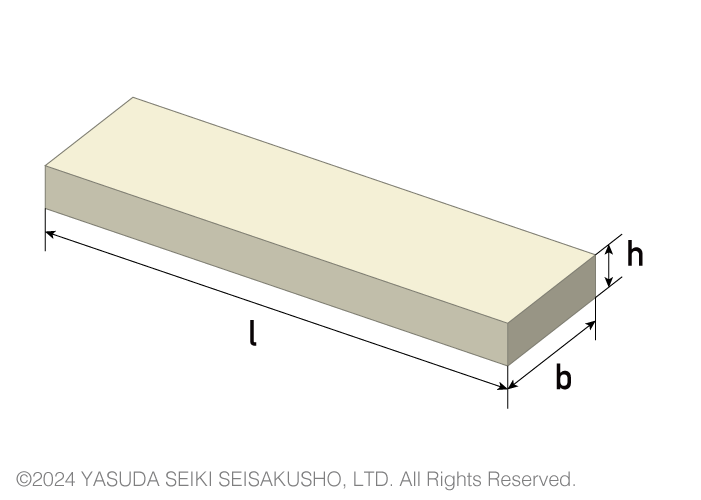

Sample Dimensions

| Standard | JIS K 7191-1,2 /ISO 75-1,2 | JIS K 7191-2 (2007) Appendix A/ ISO 75-2 (2004) | JIS K 7191-3 /ISO 75-3 | ASTM D648 |

|---|---|---|---|---|

| Test Method | DTUL FW | DTUL EW | DTUL FW | DTUL EW |

| Sample Dimensions | l=80士2.0mm, b=10士0.2mm, h=4士0.2mm |

l=120士10mm, b=9.8~15mm, h=3.0~4.2mm |

l=at least10mm longer than span between supports, b=9.8~12.8mm, h=2.0~7.0mm |

I=at least 12.7mm longer than span between supports (127mm commonly used), b=12.7士0.5mm, h=3~13mm |

| Span between Supports | 64士1mm | 100士1mm | 30h±1mm | Method A: 101.6士0.5mm, Method B: 100士0.5mm |

| Loading Edge | R3.0士0.2mm | R3.0士0.2mm | R3.0士0.2mm | R3.0士0.2mm |

| Flexural Stress | Method A: 1.80MPa Method B: 0.45MPa Method C: 8.00MPa |

Method A: 1.80MPa Method B: 0.45MPa Method C: 8.00MPa |

Equivalent to 1/1000 of the Flexural modulus | Method A: 1.82MPa Method B: 0.455MPa |

| Temperature Increase Rate | 120士10°C/h | 120士10°C/h | 120士10°C/h | 2士0.2°C/min |

According to JIS K 7191-1, sample dimensions and flexural stress are specified by K 7191-2 and K 7191-3; however, tests conducted under the conditions specified in JIS K 7191-2 are generally the most common.

Vicat Softening Temperature (VST) Tester & Ball Pressure (BP) Test

| Standard | JIS K 7206 /ISO 306 | JIS K 6816 | ASTM D1525 | Electrical Appliances and Materials Safety Act |

|---|---|---|---|---|

| Test Method | VICAT | VICAT | VICAT | BP |

| Sample Dimensions | Square plate: ≧10mm※ or circular plate: diameter ≧10mm※, thickness 3-6.5mm ※ISO306 is ≧9mm |

Width: 10-20mm, thickness:2.4-6mm, length:tube 50±5mm | Square plate: ≧10mm, thickness 3-6.5mm | Square plate: ≧15mm, thickness 3±0.5mm |

| Indenter | Cylinder: 1.5-3mm length, cross-sectional area 1.000±0.015㎟ | Cylinder: 3mm length, cross-sectional area 1.000±0.015㎟ | Cylinder: 2mm length, cross-sectional area 1.000±0.015㎟ | 5mm diameter, Grade 40 steel ball |

| Load | A50/A120 method: 10±0.2N, B50/B120 method: 50±1N | 50±1N | 10±0.2N, 50±1N | 20N+0/-0.4N |

| Temperature Increase Rate | 120±10℃/h, 50±5℃/h |

50±5℃/h | 120±10℃/h, 50±5℃/h |

– |

Water Pipe Testing (JIS K 6816)

Rigid polyvinyl chloride pipes commonly used for water supply are subject to the test items and performance criteria specified in JIS K 6742. The Vicat Softening Temperature (VST) test is one of the test items, and the testing method follows JIS K 6816.

Additionally, the Japan Water Works Association’s “Inspection Procedure for Water Supply PVC Pipes” and the AS20 “Unplasticized poly (vinyl chloride) (PVC-U) pipes for water supply” from the Japan PVC Pipe and Fittings Association also refer to JIS K 6742 for testing. Let’s take a closer look at the test methods.

Test Overview

The basic test method is based on the method B50 of the Vicat Softening Temperature (VST) test, as specified in JIS K 7206. A load of 50±1N is applied to the sample, and the sample is immersed in a heating medium that increases the temperature at a rate of 50°C/h. The temperature at which the indenter penetrates 1±0.01mm into the sample, made from water pipes or fittings, is recorded as the Vicat Softening Temperature.

Note: Unlike JIS K 7206, the heating medium is preheated to a temperature approximately 50°C lower than the expected Vicat Softening Temperature and maintained at that level prior to the test.| Sample Dimensions | Loading Edge |

|---|---|

| Width: 10-20 mm Thickness: 2.4-6 mm Length: Pipe length 50±5 mm, Joint 15-50 mm |

Indenter size: 3 mm diameter cylindrical shape Cross-sectional area: 1.000±0.015 mm² |

Yasuda Seiki’s Testing Machine: No.148 Heat Distortion Tester

Our Heat Distortion Tester can perform Deflection Temperature Under Load (DTUL) tests, Vicat Softening Temperature (VST) tests, and Ball Pressure (BP) tests. We also offer customization for existing products. For more details, please refer to the link below.

Contact Us

With over 65 years of experience in supporting the quality control and R&D of various industrial fields, Yasuda Seiki consistently aims to satisfy our customers’ various needs.

Reference Standards

- ISO 75-1 (JIS K 7191-1) Plastics — Determination of temperature of deflection under loadーPart 1: General test method

- ISO 75-2 (JIS K 7191-2) Plastics — Determination of temperature of deflection under load — Part 2: Plastics and ebonite

- ISO 75-3 (JIS K 7191-3) Plastics — Determination of temperature of deflection under load — Part 3: High-strength thermosetting laminates and long-fibre-reinforced plastics

- ISO 306 (JIS K 7206) Plastics — Thermoplastic materials— Determination of Vicat softening temperature (VST)

- Electrical Appliances and Materials Safety Act (2014) Appendix Table 3 Method B in the report on “The registration system for ball pressure temperature of thermoplastics used in electrical appliances and material.”

- JIS K 6742 Unplasticized poly(vinyl chloride) (PVC-U) pipes for water supply

- JIS K 6816 Thermoplastics pipes and fittings-Test method for Vicat softening temperature