No.214 OXYGEN INDEX FLAMMABILITY TESTER

- This tester is used to evaluate the oxygen index flammability of plastic and rubber.

- The operator is to check the lowest oxygen level (the oxygen level is acquired from a mixture gas of oxygen and nitrogen) that the test specimen is capable to flame inside the flaming column.

Specification

| Specifications are subject to change without notice. | ||

| Model | No.214 | No.214-ISO |

|

Test Chimney |

Inside diameter φ75 +3/-0 mm, |

Inside diameter ø75 +3/-0 mm, |

|

Flowmeter |

Oxygen: max. 8.6 l/min (graduation 0.1 l/min) |

Mass flow controller type |

|

Pressure Gauge |

Oxygen: max. 0.1 MPa (graduation 0.002 MPa) |

|

| Burner |

Flame height is adjustable between 6–25 mm |

|

|

Test Sample |

Plastic, rubber, textile |

|

|

Accessories |

U-shaped sample holder, glass beads |

U-shaped sample holder |

|

Options |

Thermometer (for inside the test chimney), tool for preparing rolled-film samples, specs for high temperature testing (HT model), oxygen analyzer |

|

| Power Source | ― |

AC 100 V 1-phase 5 A 50/60 Hz |

| Heat Source |

LPG or natural gas |

|

|

Gas Supply |

Oxygen, nitrogen |

|

|

Dimensions and Weight (Approx.) |

W600×D300×H580 mm, 35 kg |

W600×D270×H580 mm, 25 kg |

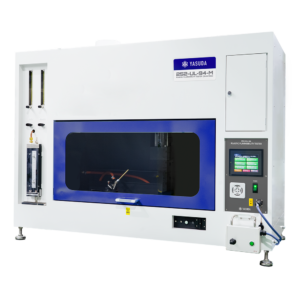

No.252-UL-94 PLASTIC FLAMMABILITY TESTER

- This tester is used to evaluate the burn-resistance of plastic according to the vertical flaming test (V) and horizontal flaming test (HB).

- The tester has been improved so that the operator can conduct the test easily by using the jog dial type controller and the touch panel display also equipped with voice guidance.

- With these functions, the operator can concentrate in watching the condition of the test specimen while controlling the burner to adjust the distance between the flame and the test specimen.

- Adding the option jigs, the tester will enable to carry out other test methods (5V, VTM, HBF, HF).

Specification

| Specifications are subject to change without notice. | ||

| Model | No.252-UL-94 (MANUAL) |

No.252-UL-94 (ELECTRIC) |

|

Fume Hood |

Approx. 1000×560×900 mm (inside volume approx. 0.5 m³) |

|

|

Test Method |

HB (for self-supporting samples), V |

|

|

Burner |

Tube length 100 ± 10 mm, inner diameter ø9.5 ± 0.3 mm |

|

|

Burner Stand |

Manually controlled by handwheel for left/right movement |

Motor controlled by joystick for left/right movement |

|

Flowmeter |

Max. 150 ml/min (graduation 2 ml/min), |

Max. 150 ml/min (graduation 2 ml/min), |

|

Manometer |

Max. 2.0 kPa (graduation 0.01 kPa) |

|

|

Accessories |

Heat resistant gloves, flame height gauge |

|

|

Burner Calibration Device |

Optional Accessory |

Standard Accessory (Built-in, touchscreen operated) |

|

Burner Calibration Accessories |

Timer (displayed on the touchscreen), temperature indicator, thermocouple and slug, slug positioning gauge |

|

|

Power Source |

AC 100 V 1-phase 3 A 50/60 Hz |

AC 100 V 1-phase 10 A 50/60 Hz |

|

Heat Source |

Methane gas (min. 98% pure) *Not included |

|

|

Dimensions and Weight (Approx.) |

Main unit: W1,400×D700×H1,220 mm ,100 kg |

W1,400×D700×H1,220 mm, 220 kg |

No.252-UL-1581 ELECTRIC WIRE FLAMMABILITY TESTER

- This tester is to evaluate the flammability resistance of electric wires by conducting a vertical flammability test.

- The operator is to fix the test specimen to the upper and lower Chuck and tilt the burner 20° to burn the test specimen for 15 seconds.

Specification

| Specifications are subject to change without notice. | |

| Chamber | 1.6 × 1.6 × 1.6 m (Volume Approx. 4 m³) |

| Specimen | L450 ± 10 mm |

| Burner | L100 ± 10 mm, Inner Diameter φ9.5 ± 0.3 mm |

| Burner Base | Inclination Angle 20° |

| Burner Calibration Device | Flow Meter: Max. 1,000 ml/min (Scale 10 ml/min) (Standard 965 ml/min) Manometer: Max. 500 (± 250) mmH2O (Scale 1 mmH2O) (Standard 125 ± 15 mmH2O) Timer, Thermometer, Slug |

| Accessories | Flame Gauge, Ring Stand, Gauge for Slug, Dry Cotton Pad |

| Power Source | Tester Body: AC 100 V, 1-Phase, 3 A, 50/60 Hz Calibration Device: AC 100 V, 1-Phase, 3 A, 50/60 Hz |

| Heat Source | Methane Gas (Purity: 98 % Over) |

| Dimensions/ Weight (Approx.) | W2,000 × D1,600 × H2,350 mm, 442 kg (Chamber) W540 × D420 × H1,100 mm, 28 kg (Calibration Device) |

No.440-S MVSS FLAMMABILITY TESTER

- This tester is used to evaluate the flammability of inner material for cars, tractors, and machines.

- Attaching the test specimen to a U-shaped specimen holder and flaming the free end for 15 seconds, the operator is to measure the flaming speed of the test

Specification

For All Models

| Specifications are subject to change without notice. | |

|

Heat Resistance Wires |

Diameter ø0.25 mm |

|

Accessories |

Sample holder set, LPG hose, hose clamp, flame height gauge |

|

Options |

Timer (for automatic control of the flame application time), heat resistance wires (spare) |

|

Power Source |

AC 100 V 1-phase 5 A 50/60 Hz (timer included) |

No.440-S1 (FMVSS, ASTM)

| Specifications are subject to change without notice. | ||

|

Test Standard |

FMVSS |

ASTM |

|

Test Sample |

Width 102 mm, length 356 mm, thickness 13 mm or below |

Width 100 mm, length 300 mm or above, thickness 13 mm or below |

|

Gas Burner |

Inside diameter ø10 mm |

Inside diameter ø9.5 ± 0.3 mm |

|

Heat Source |

Natural gas |

Methane or natural gas |

|

Sample Holder |

U-shaped with grooves (at 25 mm intervals) and markings |

|

|

Accessories |

Heat resistance wire, holder support |

|

|

Dimensions and Weight (Approx.) |

W480×D250×H580 mm, 25 kg |

|

No.440-S2 (JIS, ISO, JASO)

| Specifications are subject to change without notice. | ||

|

Test Standard |

JIS, ISO |

JASO |

|

Test Sample |

Length 356 mm, thickness 13 mm or below when width is 3–60 mm, |

Width 100 mm, length 356 mm |

|

Gas Burner |

Inside diameter ø9.5 ± 0.5 mm |

Inside diameter ø10 mm |

|

Heat Source |

Natural gas (calorific value 38 MJ/m3) |

|

|

Sample Holder |

U-shaped with grooves (at 25 mm intervals), pins, and tray |

|

|

Accessories |

Tray |

|

|

Dimensions and Weight (Approx.) |

W520×D260×H580 mm, 25 kg |

|

Inquiry Form

Contact Us For over 70 years, Yasuda Seiki’s testing machines have supported quality control and research & development across various industries, meeting the diverse needs of our clients.