-

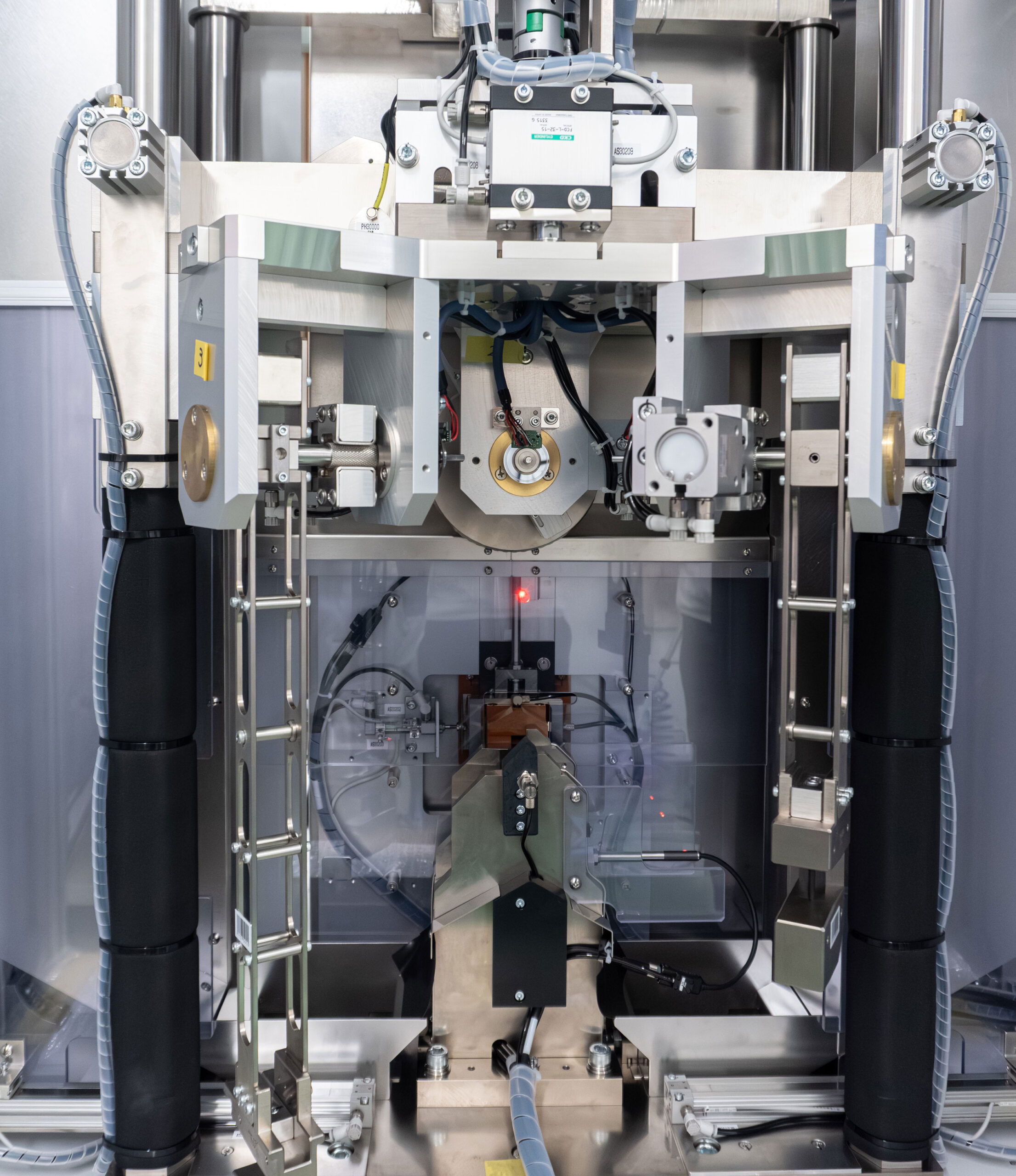

Fully Automated Impact Testing

Up to 210 Consecutive TestsSimply set the samples and input the test conditions into the dedicated software to conduct up to 210 consecutive tests. Automation reduces human error, relieves operators, and improves overall safety and efficiency.

-

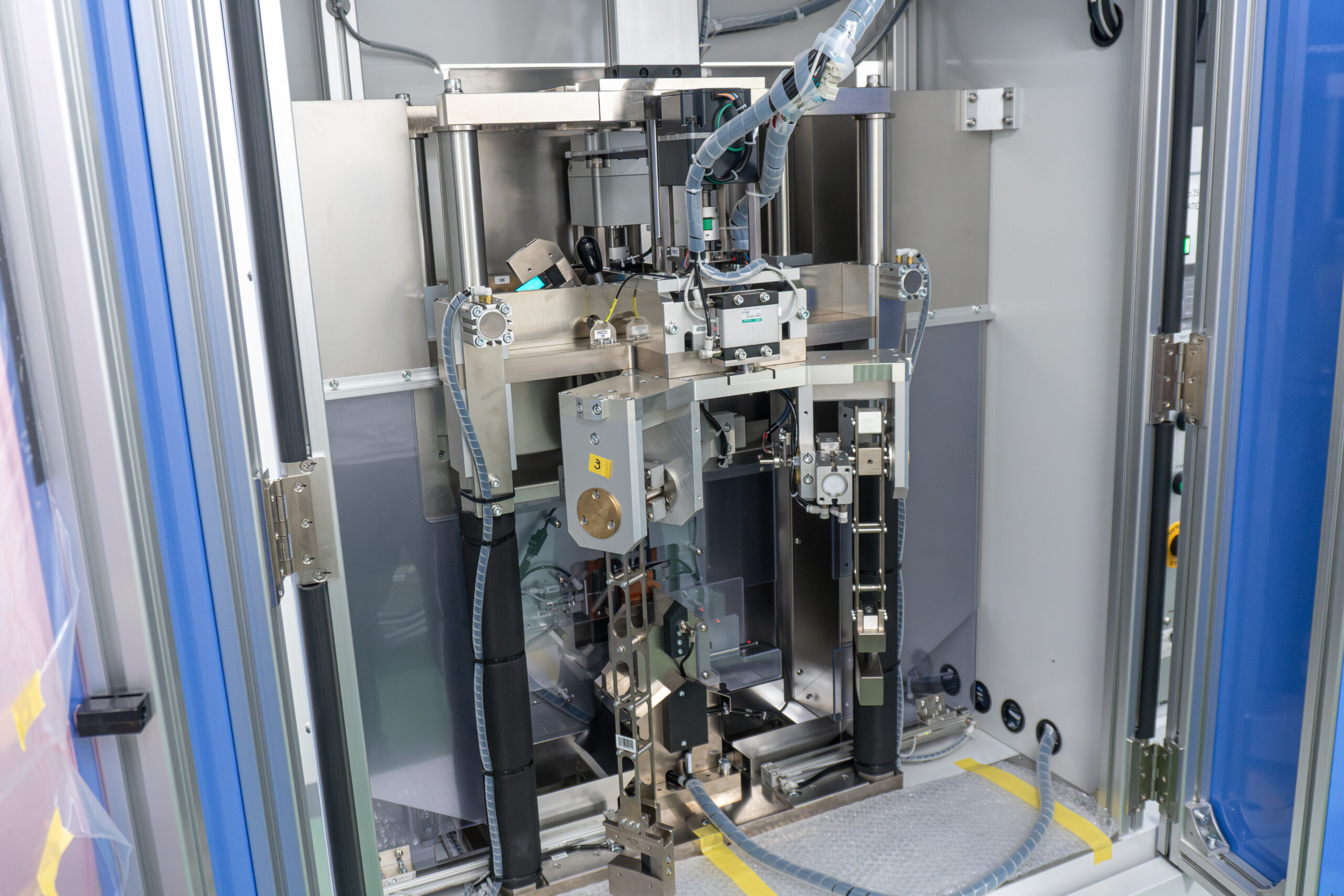

No Interruption for Hammer Replacement

Automatic Charpy Hammer Switching (3 Capacities)Three types of Charpy hammers can be automatically switched without interrupting the testing process. Even when switching between hammers with different capacities, tests can proceed continuously, significantly improving testing efficiency.

*Not compatible with Izod testing. -

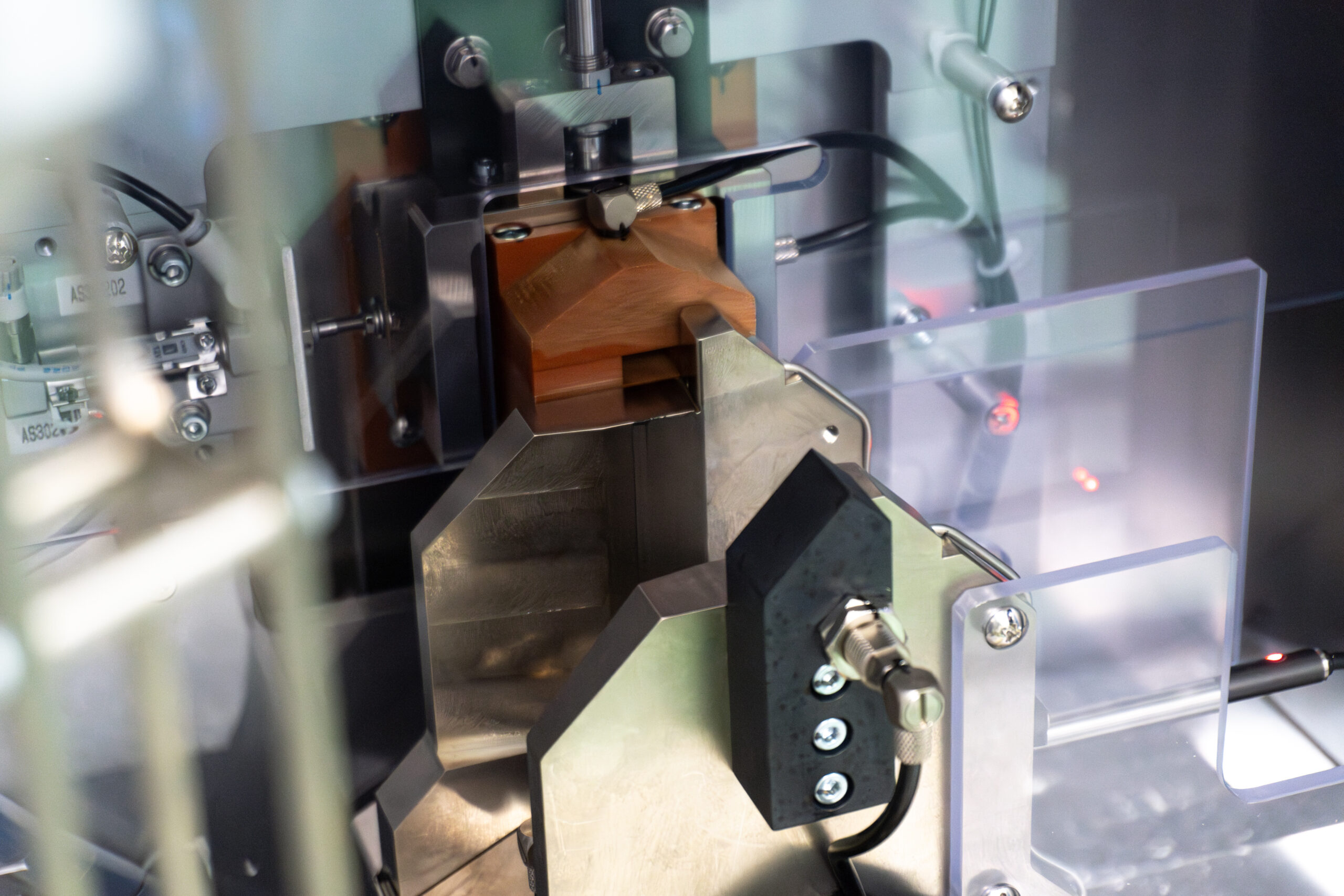

Automatic Sample Dimension Measurement

Significantly Reduces WorkloadThis function automatically measures the sample dimensions, eliminating the need for manual measurement and input. After measuring the dimensions, the sample is automatically set at the testing position. The process from measuring the sample dimensions to aligning the notch position is completed in approximately 5 seconds.

-

Sample Collection Function

Automatically Collect Designated SamplesThis function allows samples after impact to be automatically collected. By selecting the desired samples on the PC, they are collected automatically during testing. This is useful when observing the tested samples afterward.

| Temperature | Room temperature Option: -40°C to 80°C (with low-temperature chamber) |

|---|---|

| Main Unit Specifications | ・Electric hammer release ・Automatic hammer lifting mechanism ・Automatic sample setting |

| Hammer | Energy capacity 0.5–15 J (Charpy), 1–22 J (Izod), automatic lifter, automatic stopper (disc brake) |

| Anvil | Automatic sample centering device, sample residue removing device |

| Number of Samples | 70 samples × 3 cartridges (total 210 samples) *For sample size width 10 × thickness 4× length 80 mm |

| PC Software | Available for Windows |

| Power Source | AC 200 V 1-phase 10 A 50/60 Hz With low temperature chamber: AC 200 V 3-phase 30 A 50/60 Hz |

| Air Source | 0.5 MPa and above |

| Dimensions and Weight(Approx.) | W1,150×D1,050×H1,950 mm, 700 kg |

Common Specifications

| Standards | JIS/ISO | ASTM | |||

|---|---|---|---|---|---|

| Reference Standards | JIS K 7111-1,ISO 179-1 | JIS K 7110,ISO 180 | ASTM D6110-10 | ASTM D256 | |

| Test Method | Charpy Impact Test | Izod Impact Test | Charpy Impact Test | Izod Impact Test | |

| Hammer Energy Capacity (J)*1 | 0.5, 1, 2, 4, 5 | 7.5, 15, 25*2 | 1, 2.75, 5.5, 11, 22 | 2.7 and above (past results: 0.5, 1, 2, 4, 5, 7.5, 15, 25) | 2.7 to 21.7 (past results: 1, 2.75, 5.5, 11, 22) |

| Anvil Lift for Charpy | Required | – | – | – | – |

| Impact Velocity | 2.9m/s | 3.8m/s | 3.5m/s | 3.46m/s | 3.5m/s |

| Hammer Release Angle | 150° | ||||

| Hammer | Refer to the respective sections below for details. | ||||

| Anvil | Refer to the respective sections below for details. | ||||

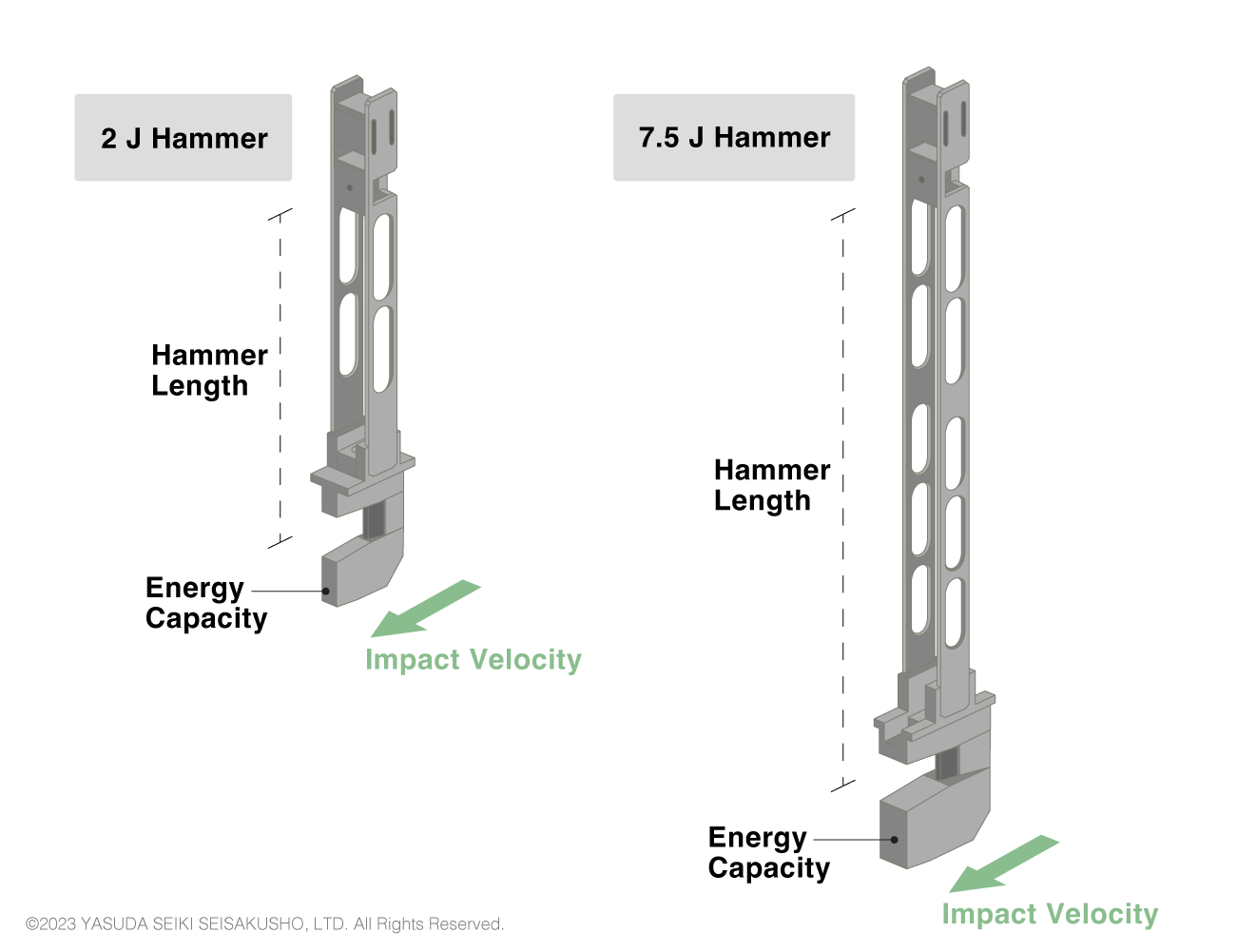

Hammer

| Standard | Potential Energy | Impact Velocity | Angle of Striking Edge | Radius of Striking Edge |

|---|---|---|---|---|

| ISO/ JIS |

0.5J | 2.9m/s | 30±1° | R2±0.5mm |

| 1J | ||||

| 2J | ||||

| 4J | ||||

| 5J | ||||

| 7.5J | 3.8m/s | |||

| 15J | ||||

| 25J | ||||

| ASTM | 2.7 and above (past results: 0.5, 1, 2, 4, 5, 7.5, 15, 25) | 3.46m/s | 45±2° | R3.17±0.12mm |

The characteristics of the Charpy hammers differ between the test standards as shown in the table above. In ISO and JIS standards, the hammer length changes according to the impact velocity. Therefore, the same hammer cannot be used to create, for example, a 4 J impact and 7.5 J impact. Two different hammers must be prepared.

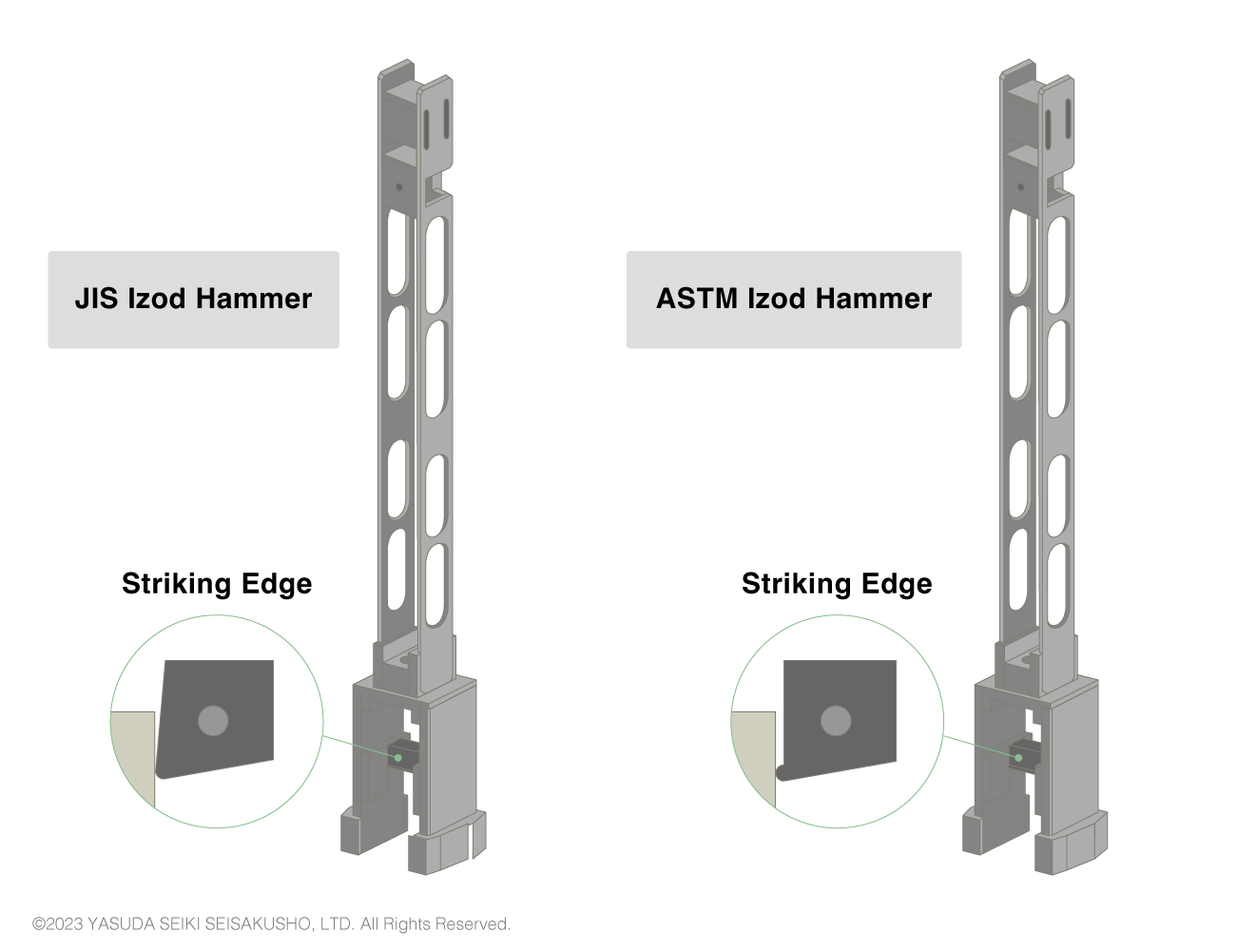

| Standard | Potential Energy | Impact Velocity | Radius of Striking Edge |

|---|---|---|---|

| ISO/ JIS |

1J | 3.5m/s | R0.8±0.2mm |

| 2.75J | |||

| 5.5J | |||

| 11J | |||

| 22J | |||

| ASTM | 2.7-21.7J | 3.5m/s | R0.8±0.2mm |

The same hammer is sometimes used between ISO (or JIS) and ASTM impact tests as the details of the hammers specified in the two standards are similar. However, to be precise, the shape of the striking edge differs between the standards as shown in the above image. Therefore, to conform to the test standards, hammers that match the test standard shall be used.

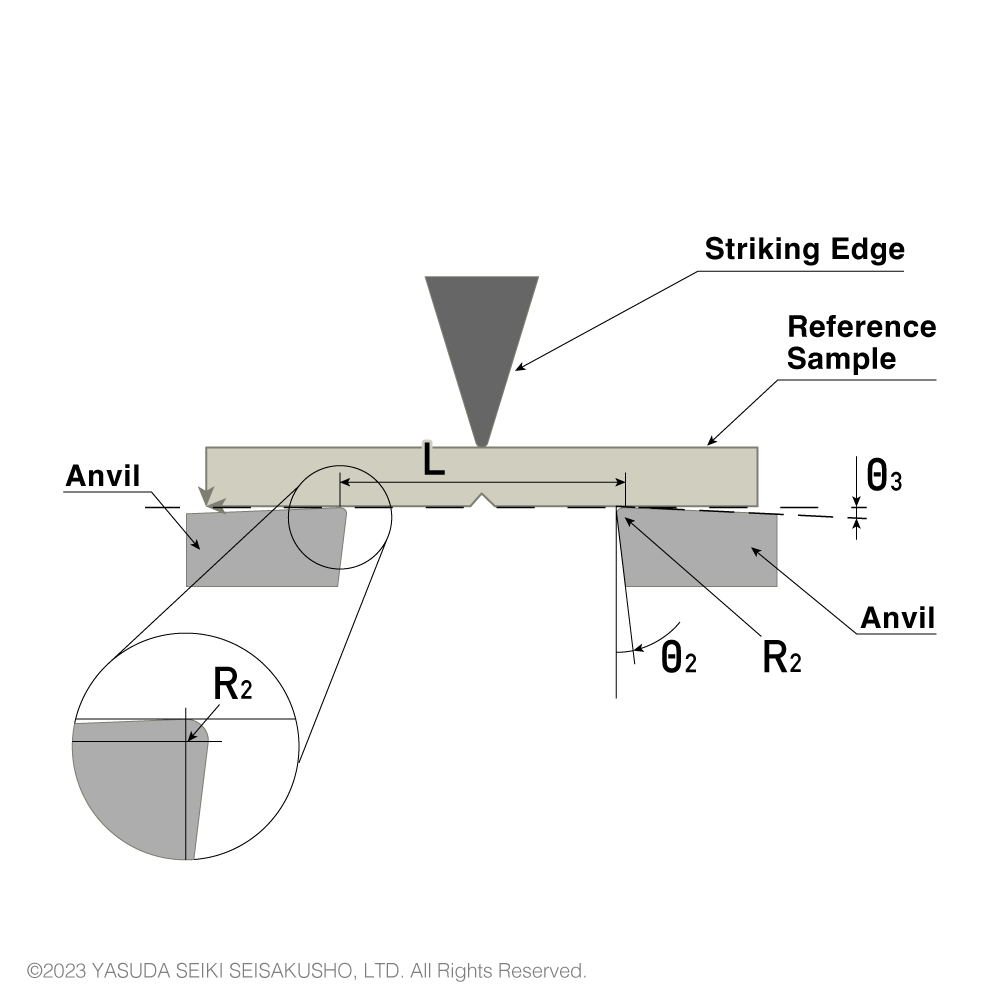

Anvil

| Symbol | Parameter | ISO/JIS | ASTM |

|---|---|---|---|

| ー | Parallelism between long axis of test sample and reference plane | ±4/1000 | ー |

| R2 | Radius of curvature of anvils | 1±0.1 mm | 3.17±0.12 mm |

| θ2 | Angle of taper of anvils | 10±1 ° | 0 |

| θ3 | Angle of slope of anvils | 5±1 ° | 0 |

| ー | Angle of supports and anvils | 90±0.1 ° | 90° |

| L | Span between sample supports | 62±(0.5/0) mm | 101.6±0.5 mm |

The shape of the anvil differs between ISO (or JIS) and ASTM standards. Therefore, to perform both ISO and ASTM standardized tests, two different anvils shall be prepared.

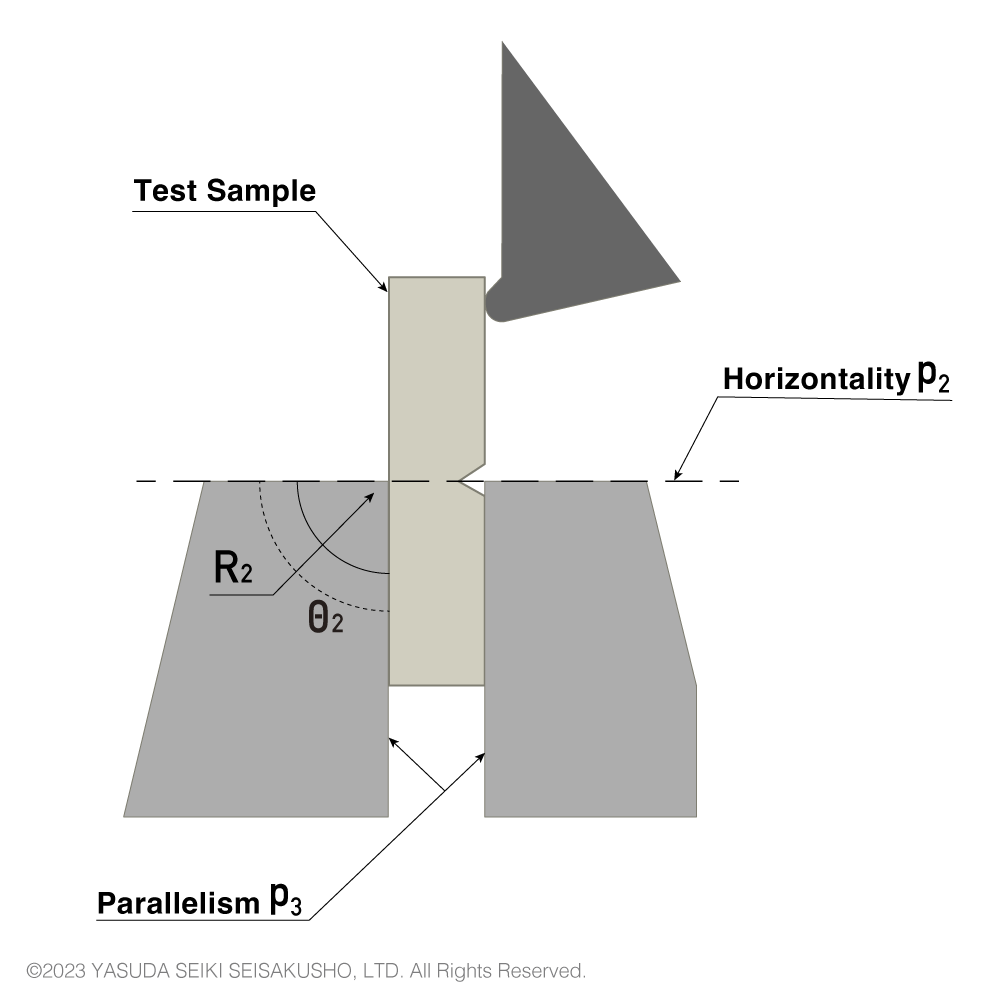

| Symbol | Parameter | ISO/JIS | ASTM |

|---|---|---|---|

| ー | Sample angle | 90±2 ° | ー |

| ー | Parallelism with face of reference sample | ±0.025 mm | ー |

| P2 | Horizontality of top surface of vise | ±3/1000 | ー |

| θ2 | Angle between support block and top surface of vise | 90±0.5 ° | ー |

| P3 | Parallelism in horizontal and vertical direction | ±0.05 mm | ー |

| R2 | Top edge radius of support | 0.2±0.1 mm | 0.25±0.12 mm |

In strict terms the anvil shapes differ between ISO (JIS) and ASTM standards, but are sometimes used mutually as the differences are minor.

This function automatically measures the dimensions of the sample, eliminating the need for manual measurement and input, thereby significantly reducing workload.

This function allows for the automatic switching between three hammer capacities. Even when hammers with different capacities are used, the tests can be proceeded continuously without interruptions caused by hammer replacement.

This function automatically collects tested samples. By selecting the desired samples on the PC software, they are automatically retrieved after impact. This is particularly useful when samples need to be inspected after testing.

Adjusts the height of the hammer when using hammers of different lengths.

Equipped with a built-in low-temperature chamber, this function supports testing at temperatures as low as -40℃.

Contact Us

For over 70 years, Yasuda Seiki’s testing machines have supported quality control and research & development across various industries, meeting the diverse needs of our clients.