Operation Video

-

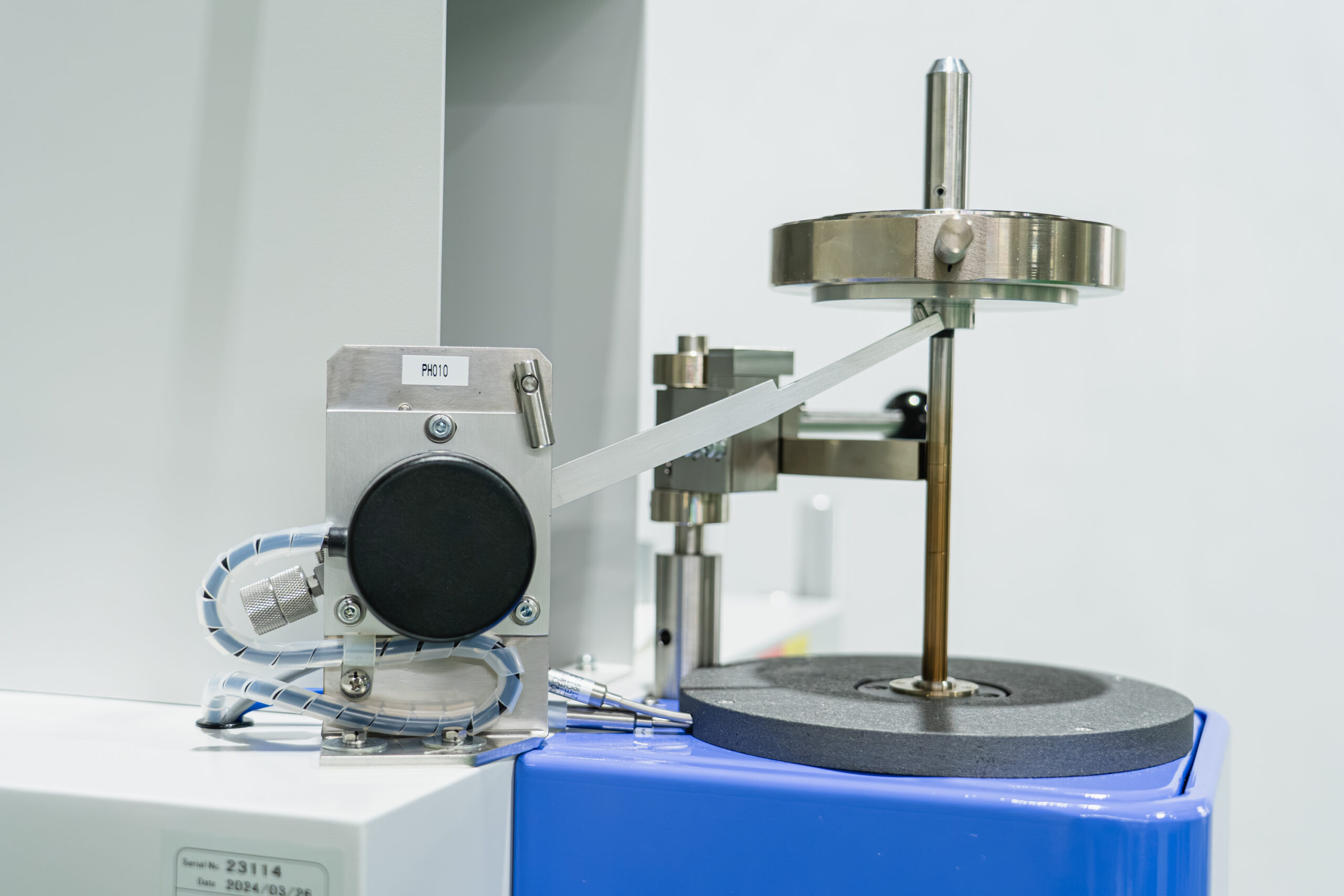

Rotary Encoder Standard-Equipped

Supports both Procedure A and Procedure B Testing in Standard ConfigurationThe rotary encoder is standard-equipped, allowing Procedure A and Procedure B testing in the standard configuration. Additionally, during Procedure A testing, the rotary encoder precisely tracks the piston position, ensuring accurate measurements between standard markings as required by respective test standards, regardless of the operator’s skill level.

-

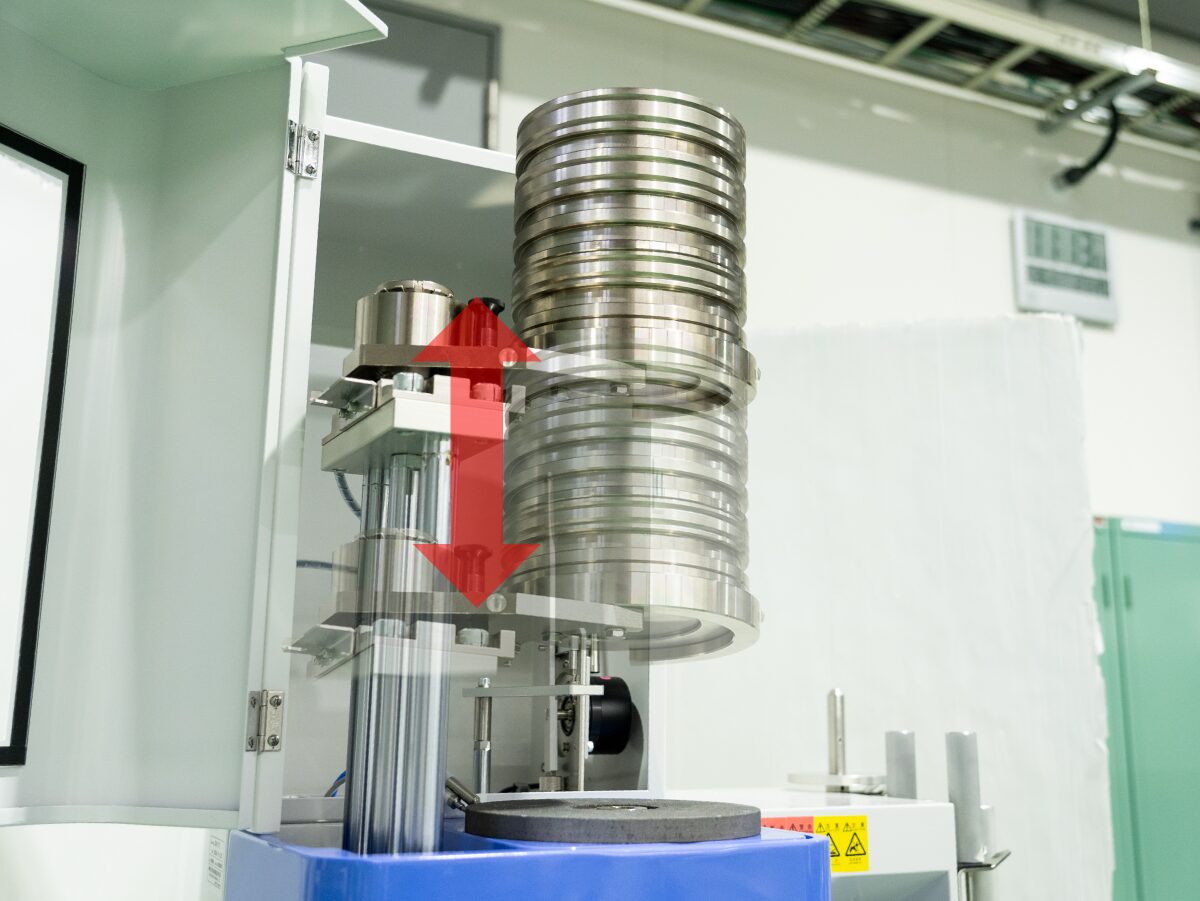

Automated Sample Cutting

Pneumatic Procedure A CutterDuring Procedure A testing, molten samples are automatically cut. In melt flow testing, handling high-temperature samples is potentially hazardous as hands may come near heated areas, and sample temperatures are also high. Operator experience may also lead to variations in test results. The adoption of this automated cutter enhances safety and reduces human error.

-

Large Full-Color Touchscreen

Applicable for Validating Data QualityManual MFR testing requires precise timing. This model features a large, full-color touchscreen with high visibility, helping prevent operational mistakes during testing. Preheating and testing times (cutting intervals) are visualized with a progress bar, and the buzzer signals the cut timing, making operation easier. After testing, simply input the sample mass to automatically calculate, display, and save the MFR value. The device supports four languages: Japanese, English, Chinese, and Korean.

| Reference Standards | JIS K 6719-1/2, K 6921-2, K 6922-2, K 6923-1, K 6924-1, K 6926-2, K 7210-1, ISO 1133-1, ASTM D1238 |

|---|---|

| Number of Samples | 1 sample per test |

| Die | φ2.095 ± 0.005 mm, L8.000 ± 0.025 mm |

| Piston | Head Diameter φ9.474 ± 0.007 mm, Head Length L6.35 ± 0.10 mm |

| Cylinder | Inner φ9.550 ± 0.007 mm, L160 mm |

| Temperature Range | Max. 400 ℃ |

| Initial Weight | 0.325 kgf |

| Additional Weight | 1.20 – 21.60 kgf (* See Option Tab) |

| Test Method | Method A: Manual (Option: Automatic) Method B: Automatic |

| Sample Feeding | Manual |

| Weight Loading | Manual (Option: Automatic) |

| Weight Change | Manual |

| Cylinder Cleaning | Manual |

| Die Cleaning | Manual |

| Piston Cleaning | Manual |

| Data Processing | Method A: Automatic (Measuring the weight of the cut off sample is done by hand) Method B: Automatic |

| Method B Measuring | Rotary Encoder |

| Power Source | AC 100 V, 1-Phase, 15 A, 50/60 Hz or AC 200 V, 1-Phase, 10 A, 50/60 Hz |

| Air Source | 0.5 MPa or More (For Method A Cutting Device / Pneumatic Weight Loading Device Specification) |

| Dimensions / Weight(Approx.) | No.120FWP: W660× D450 × H1,020 mm/75 kg Pneumatic Weight Loading Device Specifications: W710 × D450 × H1,060 mm/ 120 kg |

Contact Us

For over 70 years, Yasuda Seiki’s testing machines have supported quality control and research & development across various industries, meeting the diverse needs of our clients.