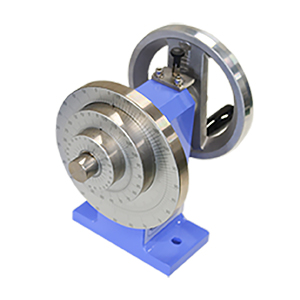

No.163-SB ENAMELED WIRE STIFFNESS TESTER (SPRING BACK METHOD)

JIS (C3003), C3216-3, IEC-60851-3

- Insert one end of the wire sample into the stopper hole on the mandrel and hang a weight on the other end.

- Wind the sample around the mandrel three times at a rotational speed of 5–10 times per minute, mark the sample, and then remove the weight.

- Slowly unwind the sample from the mandrel and read the scale at the position where the mark is located to evaluate its softness.

Specification(the spring back method)

| Specifications are subject to change without notice. | |

| Specimen | 1 m, Conductor Diameter φ0.25 to φ1.6 mm |

| Mandrel Rotation Speed | 5 to 10 rpm |

| Mandrel Diameter | φ19 mm、 φ48 mm、 φ82 mm |

| Weight | 57 g, 115 g, 455 g |

| Scale | 0 to 120 |

| Dimensions/ Weight (Approx.) | W128 × D190 × H184 mm/ 6.1 kg |

No.163-HC ENAMELED WIRE STIFFNESS TESTER (SPRING BACK ANGLE OF A HELICAL COIL)

JIS C3216-3, IEC-60851-3

- Insert one end of the wire sample into the stopper hole on the mandrel and hang a weight on the other end.

- Wind the wire sample around the mandrel five times at the specified rotational speed, mark the sample, and then remove the weight.

- Slowly unwind the sample from the mandrel and read the scale at the position where the mark stopped to evaluate its softness.

Specification(the spring back angle of a helical coil)

| Specifications are subject to change without notice. | |

| Specimen | 1 m, Conductor Diameter φ0.08 to φ1.6 mm |

| Mandrel Rotation Speed | 1 to 3 rpm |

| Mandrel Diameter | φ5 mm, φ7 mm, φ10 mm, φ12.5 mm, φ19 mm, φ25 mm, φ37.5 mm φ50 mm |

| Weight | 0.25 N, 0.5 N, 1 N, 2 N, 4 N, 8 N, 12 N, 15 N, |

| Scale | 0 to 72 |

| Dimensions/ Weight (Approx.) | W128 × D190 × H184 mm/ 4.3 kg |

Inquiry Form

Contact Us For over 70 years, Yasuda Seiki’s testing machines have supported quality control and research & development across various industries, meeting the diverse needs of our clients.