Series Overview

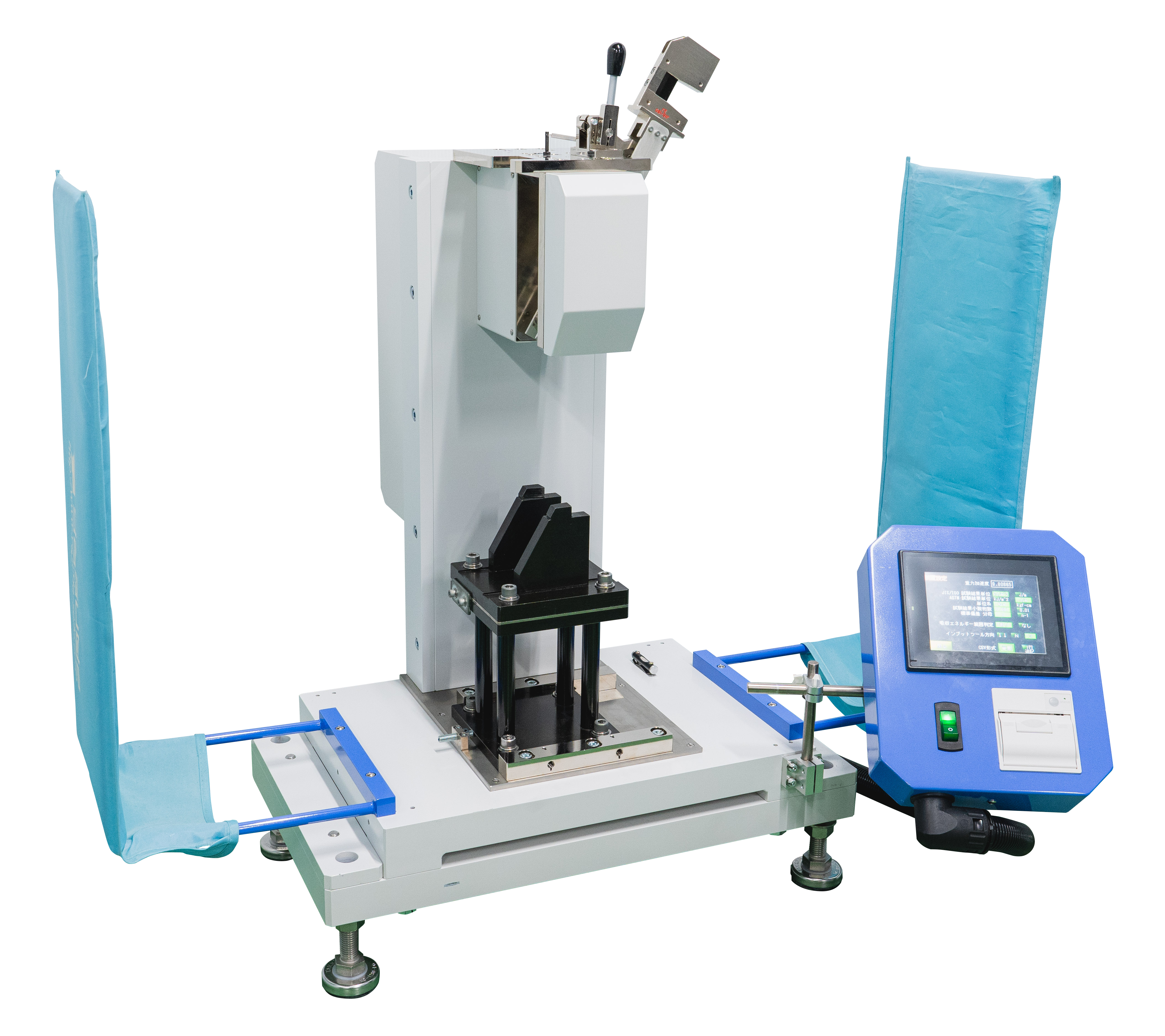

Impact testers evaluate impact resistance and toughness by applying an impact force to a sample. The impact energy, measured when a hammer strikes the sample, determines the material’s impact strength.The testing methods include the Charpy Impact Test and Izod Impact Test. The Charpy Impact Test is where the sample is supported at both ends and struck on the back of the notched section, and the Izod Impact Test is where one end of the sample is fixed, and the other end is struck from the notched side.

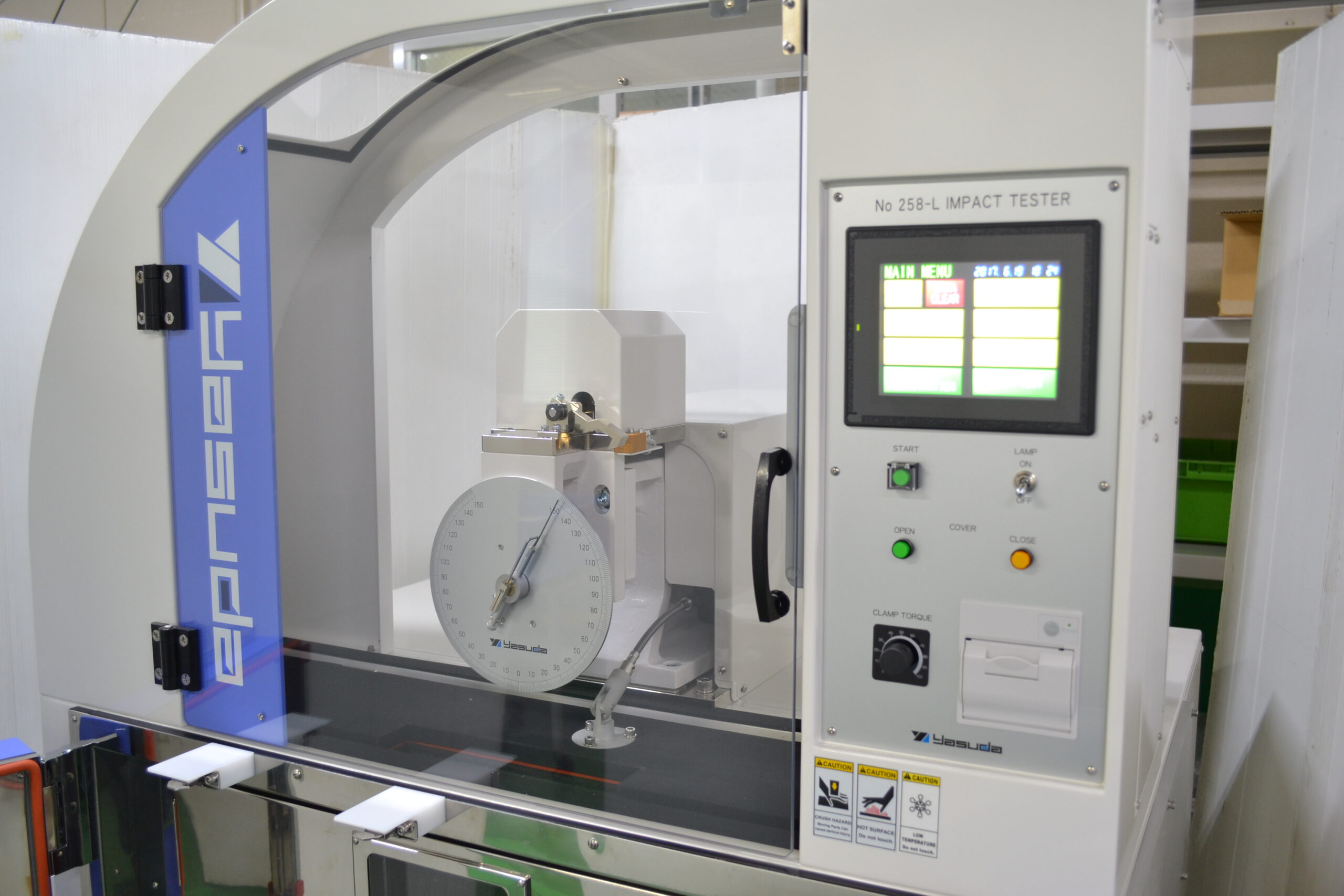

The 258 Series offers four models to provide optimal solutions tailored to specific customer needs. All models are designed and manufactured in compliance with industrial standards such as JIS, ISO, and ASTM.

Additionally, the entire series prioritizes usability and safety. The high-end model, No.258-ZA Impact Tester (Full Automatic), completely automates the testing process, bringing efficiency and accuracy to a totally new level in quality assurance and research & development environments.

Reference Standards

- JIS K 7111-1, K 7110, B 7739

- ISO 179-1, 180, 13802

- ASTM D256, D6110

*This product is designed for plastic impact testing; it is not compatible with metal samples.

Key Features of the 258 Series

-

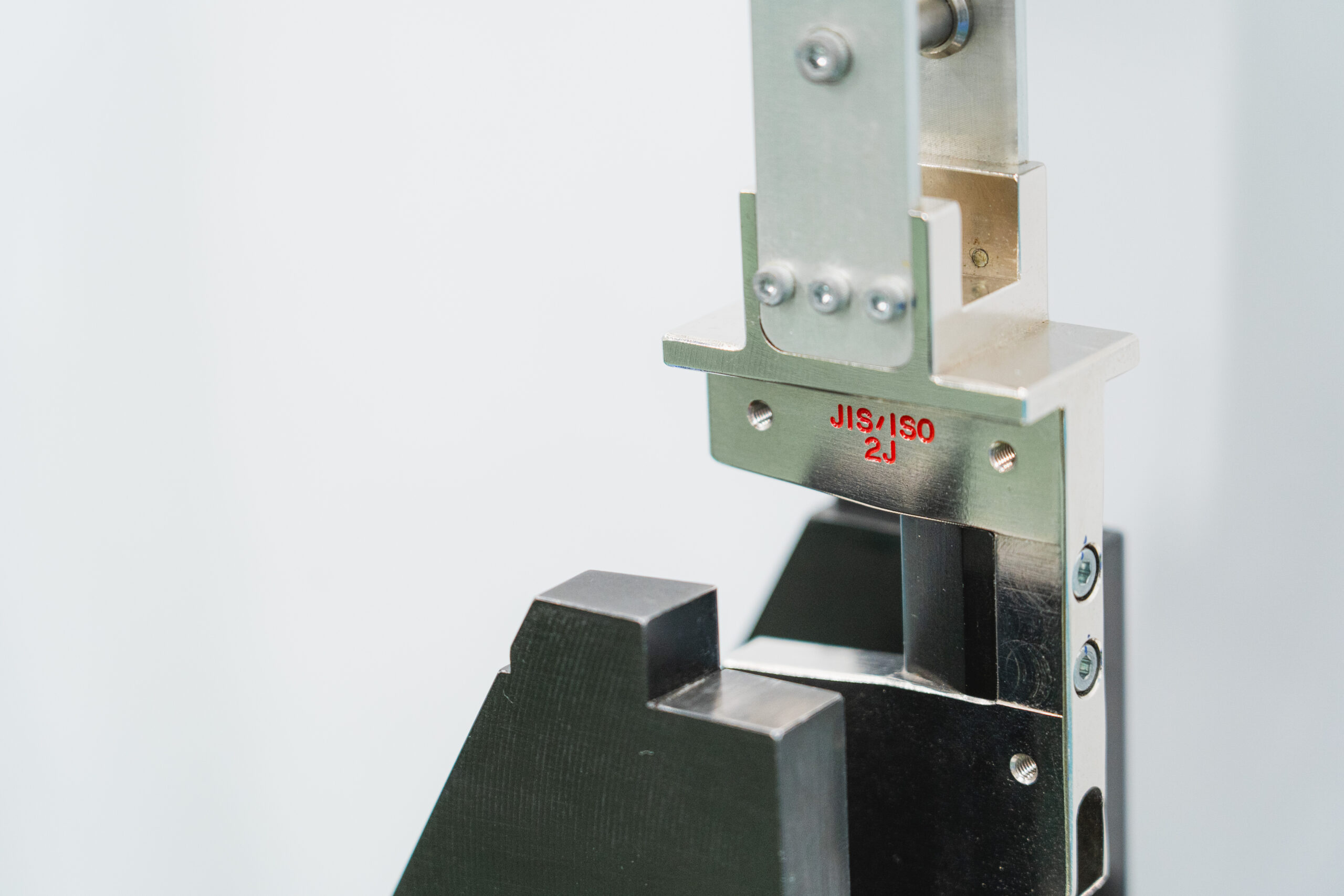

Versatile Test Compatibility

By replacing the hammer and anvil, the tester can be used to perform both Charpy and Izod impact tests accordingly. Depending on the selected specifications, the tester can comply with specifications specified in JIS, ISO, and ASTM standards.

-

Wide Temperature Range

We provide means of testing across a wide range of temperatures, from -50℃ to 80℃.

-

Comprehensive Lineup and Options

From simple manual models to full automatic systems, the 258 Series offers a broad lineup to meet diverse testing needs. A wide range of safety options and custom features is also available for each model.

Product Lineup

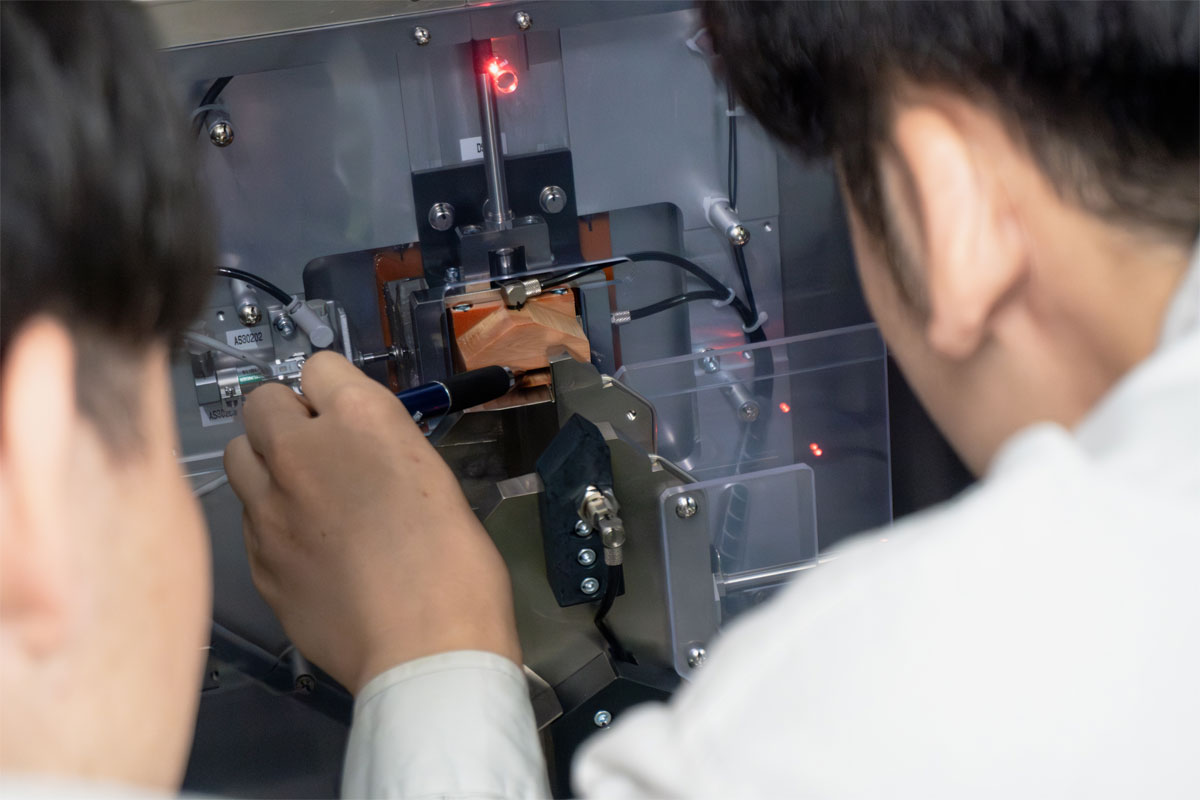

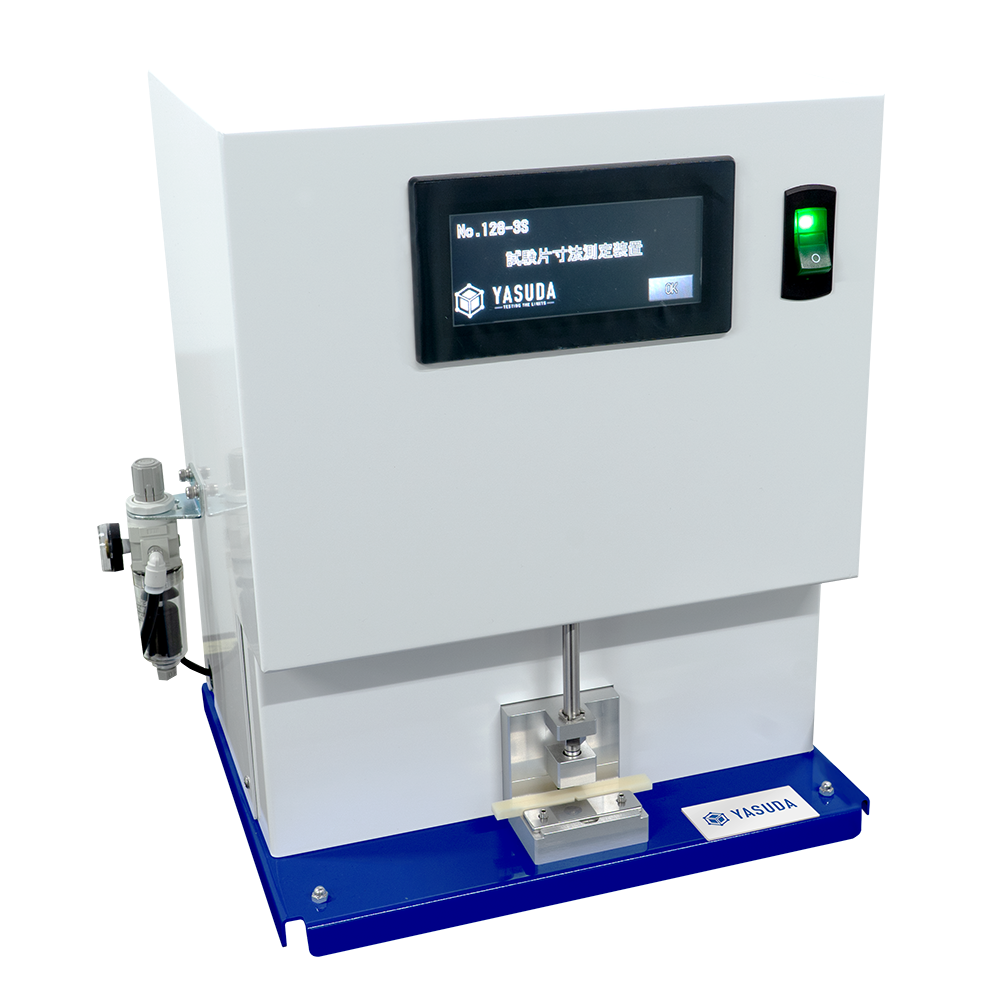

No.128-3S SAMPLE DIMENSIONING DEVICE (AUTOMATIC)

This device automatically measures the dimensions of impact test samples. Simply place the sample and press the measurement button on the touchscreen to measure the remaining width at notch tip and thickness swiftly and easily.

By reducing the time required for dimension measurements, this device significantly improves testing efficiency. When connected to the impact tester, the measured sample dimensions are automatically transferred.

Function Comparison

| Model | 258-D / 258-PC | 258-L | 258-UTL | 258-ZA |

|---|---|---|---|---|

| Product Image |  |

|

|

|

| Testing Temperature | – | -35℃ to 60℃ | -50℃ to 60℃ | -40℃ to 80℃ (with low-temperature chamber)* |

| Operation Method | Touchscreen or PC | Touchscreen | Touchscreen | PC |

| Hammer Operation | Manual | Electric Hammer Release Hammer Brake* |

Electric Hammer Release | Electric Hammer Release Automatic Hammer Lifting Automatic Charpy Hammer Switching* |

| Sample Dimension Measurement | Manual | Manual | Manual | Automatic Sample Dimension Measurement* |

| Additional Features | Full Safety Cover* | – | – | Tested Sample Collection Function* |

| Key Points |

|

|

|

|

| Product Page | View Details | View Details | View Details | View Details |

Contact Us

For over 70 years, Yasuda Seiki’s testing machines have supported quality control and research & development across various industries, meeting the diverse needs of our clients.